Automated Inspections. Any Asset, Any Angle!

From Vision to Insight: How 3D Viewing Changes Asset Inspections

Asset owners today are responsible for an increasingly diverse portfolio including solar farms, bridges, substations, pipelines, and transmission networks, each with its own inspection requirements, regulatory standards, and environmental constraints. Yet despite advances in sensors and automation, inspection methods remain largely fragmented and asset specific.

A report from gNext Labs highlights that “traditional infrastructure inspections have relied on manual, labour-intensive methods… as the nation’s roads, bridges, and public assets age and deteriorate, traditional workflows are struggling to keep up.” This fragmentation results in inconsistent data capture, delayed reporting, and higher operational costs for asset owners.

In the solar industry, scalability and environmental exposure create unique challenges. Autonomous inspection company Energy Robotics notes that maintaining solar farms with thousands of panels across remote sites requires repeatable, data-driven workflows to detect faults and soiling efficiently. Meanwhile, researchers publishing in Solar Energy observe that inspection solutions “still face challenges in data availability, real-time monitoring, computational efficiency, and dataset standardisation,” limiting automation potential across large photovoltaic assets.

For pipelines and oil and gas assets, inspection remains constrained by access, geography, and data integration. The US Department of Energy identifies major hurdles including "buried and remote pipeline segments, non-piggable lines, and limitations in existing inspection tool adaptability". A separate MDPI Sensors review adds that although technologies have improved, pipeline inspections still struggle with “detection accuracy, efficiency, and high operational costs,” particularly in complex environments.

Even within bridges and civil infrastructure, manual methods continue to dominate. MindFoundry reports that “limitations in inspection methods have led to a fragmented understanding of bridge health, and today one in every 25 council-maintained bridges is classified as substandard,” reinforcing the industry-wide need for scalable digital solutions.

Across all asset classes, the pattern is clear: inspection workflows remain disconnected, costly, and inconsistent, making it difficult to compare data across portfolios or build predictive maintenance models. The next generation of inspection technology must unify these processes under a single, standardised framework that can scale seamlessly from a bridge to a solar array to a pipeline corridor.

Automation, Intelligence, and Vision, All in One Platform

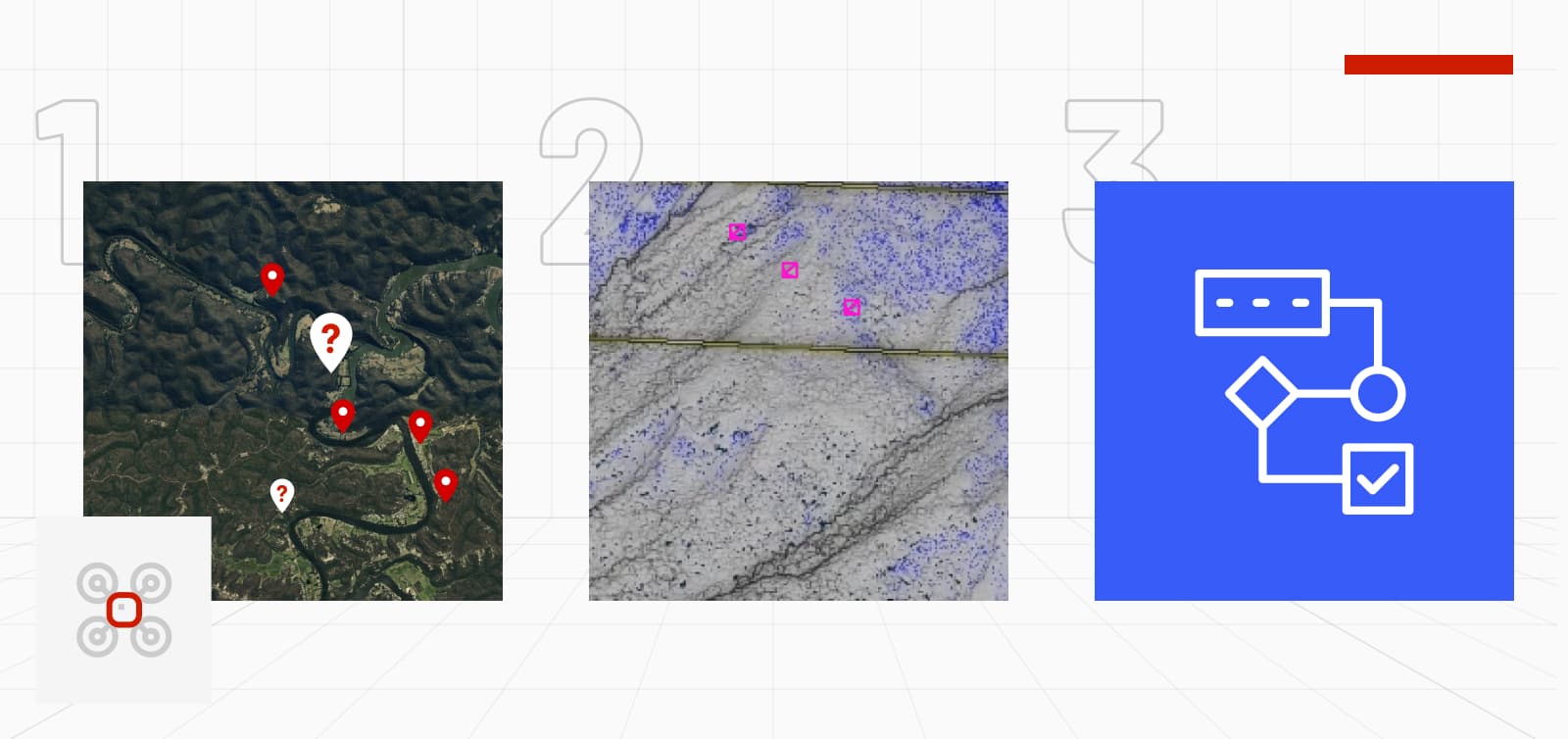

1. A Single Workflow for Any Asset

Unleash live’s Waypoint Automation allows operators to define repeatable missions around any structure, such as powerlines, solar arrays, buildings, or bridges, with centimetre-level precision. The mission architecture remains the same, while parameters like altitude, angle, and distance adjust to the asset.

2. AI-Driven Smart Inspection

Once data is captured, the Smart Inspection engine automatically analyses imagery for anomalies, defects, or degradation patterns. Whether steel trusses, solar modules, or high-voltage insulators, the same AI architecture identifies issues in context using Unleash live’s AI-App Store and Media Drive.

3. The 3D Viewer: Visualising Possibility

The 3D Viewer brings this capability to life. By rendering complex assets such as the Sydney Harbour Bridge in high fidelity, Unleash live’s platform can model inspection missions virtually before deployment.

Users can pan, zoom, and simulate inspection paths, visualising what an automated capture would look like, from under-deck geometry to tower structures and connecting spans.

This virtual demonstration illustrates scalability in action. If the workflow can handle a bridge of this complexity, it can handle any asset in an organisation’s portfolio.

Harbour Bridge autonomous asset monitoring demonstration.

Why It Matters

- Consistency Across Assets: Standardised data capture, storage, and AI-driven analysis for every asset type.

- Reduced Risk: Virtual mission simulation identifies obstacles and optimises capture before deployment.

- Scalable Deployment: A single workflow usable across energy, infrastructure, and transport sectors.

- Smarter Decisions: Unified data enables cross-asset analysis and predictive maintenance.

Looking Ahead

The Sydney Harbour Bridge 3D model demonstrates the power of a single, unified inspection workflow applied at scale. By combining automated capture, AI-driven analysis, and interactive 3D visualisation, Unleash live allows operators to inspect any asset, in any environment, with consistency and precision. This approach reduces risk, lowers costs, and enables smarter, data-driven decisions across diverse portfolios, from energy networks and pipelines to solar farms and critical infrastructure.

With Unleash live, organisations can move confidently into a future where inspections are safer, faster, and fully automated, turning complex visual data into actionable insights.