Centralized control is a new way inspectors manage their workflows, consolidating all the relevant data into one easily accessible location. By using powerful inspection tools, inspectors realize significant benefits in their operations. This article will explore the five main benefits of centralized inspection workflows.

A typical inspection workflow has two steps:

-

Step 1 Data collection. An inspector or team of inspectors collects inspection data in the field

-

Step 2 Data analysis. The data is analyzed and turned into an inspection report

The inspector's report will usually call out potential problem areas found during the inspection, highlighting flaws or defects that may need monitoring, issues requiring further attention, or even maintenance requirements.

The report can then be distributed to the maintenance manager and their team to make maintenance determinations, to other engineers concerned with the asset's health, and to those in leadership who are invested in tracking the operations of the company’s assets.

The process is predictable and repeatable. However, it can also be slow and inefficient due to a lack of centralized control for how the inspection data is captured, saved, and shared.

What Is Centralized Control?

The traditional inspection workflow described above has a decentralized control model. Data comes in from different points and is stored in different locations and reported to different stakeholders, making it hard or even impossible for stakeholders to access all the data they need through one location.

On the other hand, centralized control is a new way inspectors manage their workflows, consolidating all the relevant data and insights in one easily accessible location.

This approach to inspection workflows requires the use of new inspection tools. These tools allow multiple stakeholders to access the same data in the same place at any time so that multiple parties can easily view a dataset from one inspection, and data from several inspections of the same asset can be connected over time for monitoring purposes.

But centralized control isn’t just about data storage.

It also describes the ability to manage and use inspection data in a way that will be useful for the different stakeholders involved in maintenance, allowing them to tag, sort, and filter different types of media like photos, videos, and 2D or 3D models to manage their data and get the outputs they need from it.

Supported by new tools, inspectors are using centralized control to realize several benefits in their operations—keep reading to learn the five main benefits companies are realizing from using centralized control in their inspection workflows.

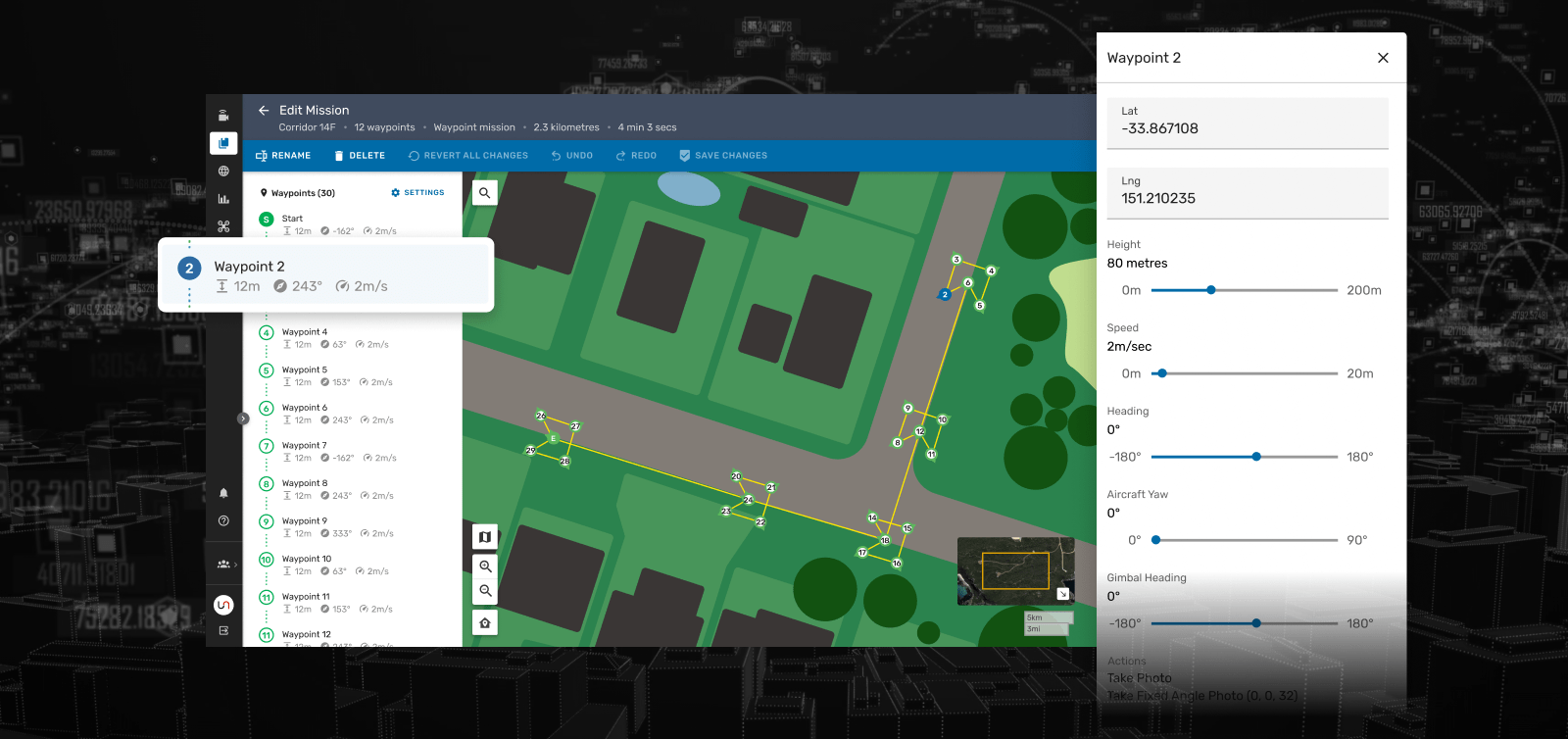

Unleash live improves workflows from data capture through to analysis and insights

1. Save and Share the Same Data across Teams

Siloed data is hard to work with. But it’s not uncommon for inspections to store some data in one place and others in another.

Data siloing can happen due to differentiation of data types, such as using RGB, thermal, and LiDAR sensors during an inspection, resulting in different data files requiring different storage and processing types.

This problem can be exacerbated by software needs when one type of software is required to process one type of data but not another, resulting in disparate outputs that need to be stored—and viewed—in different software.

With centralized control, all the data tied to a single inspection or multiple inspections of the same asset can be saved and shared across multiple teams from the cloud, allowing multiple team members to access and manage it.

2. Include All Stakeholders in the Inspection via Real Time Live Streaming

When we talk about saving and sharing data, we’re talking about the second step of the inspection process—the step after data collection.

But if you get the wrong data in the first place, data analysis and reporting aren’t impossible.

New tools are helping improve inspection data by providing high-quality live streaming during data collection.

Using live streaming, SMEs (Subject Matter Experts) can watch the screen of a drone in flight and ask the pilot to go back or to get a different angle, ensuring that the data they need is collected the first time. Or they can remotely view the data captured via mobile phones or a headset. Multiple live streams can be connected simultaneously, allowing all the data collection feeds for a single inspection to be viewed simultaneously.

A live view of drone video in Unleash live's Remote Cockpit

Imagine a single SME sitting in a central office, watching inspection live streams from locations around an entire country over the course of one day. To participate in each inspection would have required days of travel time, but live streaming allows the SME to lend their expertise with no delays for travel, placing them exactly where they need to be to ensure correct, comprehensive data collection the first time out.

And because the data is pushed directly to the cloud, the SME can review it quickly while the team is on-site, ensuring they have everything needed before they leave for the day.

3. No Lost Data

When inspectors work manually by taking photos and videos themselves, they run the risk of losing the data they collect before they have a chance to upload it to a server or the cloud.

An inspection operation that uses a centralized control tool doesn’t run this risk since a drone or mobile phone can sync its data to the cloud as it flies or right after landing.

No USB stick, PC connection, or intermediary steps are required, and there’s no chance of losing data because the data is already in the secure cloud as soon as it’s captured.

4. Find Exactly What You Need, When You Need It

A common data issue for inspectors and inspection programs, in general, is how to manage the huge amounts of data that go into maintenance efforts.

Naming conventions help, but they’re just a starting place. A good centralized control solution will allow you to find the data you need quickly and categorize it to search according to your needs.

Here are some of the ways centralized control can help you manage your data:

-

By allowing you to tag, sort, filter, and access your data (images, videos, and 2D/3D models, as well as analytics and reports)

-

By providing intuitive navigation with helpful information like metadata and file information

-

By letting you use built-in annotations so you can highlight flaws, describe their severity, and include comments for other team members

Unleash live's Media Drive and annotation tools allow for intuitive annotation and review

5. Connected Inspections

A connected inspection refers to connecting a live inspection with the background and reference information available for the asset being inspected, connecting information from the present with historical information.

Doing this allows you to review asset data in real time and quickly identify changes or issues compared to previous inspection data.

Centralized control makes it easy to connect inspections, allowing team members to access previous inspection data for the same asset to track changes over time.

Connected inspections can be incredibly powerful for asset monitoring since they can reveal potential flaws and show how they have developed over time.

Want to Implement Centralized Control in Your Inspections?

Unleash live’s Media Drive is a tool made to help inspectors centralize all of their work in one place, allowing you to implement centralized control in your inspection workflows.

Along with Media Drive, Unleash live offers high-quality, low-latency live streaming to support real-time inspection data collection, allowing SMEs to be involved even when they can’t be there in person.