Here's how Autofly Is Changing the Game for Energy Inspections

Data is the lifeblood of inspections

Since inspections were first formalized and recognized as a profession, they have been done in person. For visual, nondestructive inspections—one of the most common kinds of inspections in the energy sector—an inspector would go to the asset that needed to be inspected and carefully look at every area of interest, taking notes and photos as they progressed. After collecting data, the inspector would analyze it to produce a final report with their findings.

Today, many inspectors still collect data in person, climbing utility poles to inspect the condition of power lines or entering the confined space inside an industrial boiler to look for cracks in the welds that hold it together.

But new tools like drones and robot crawlers allow inspectors to get the visual data they need remotely without placing themselves in potentially dangerous scenarios. By flying a professional drone up to a power line or into a boiler, the inspector can remain safely outside and get all the necessary visual data. And now, the huge quantities of data drones collect have created a new problem: how to store it, manage it, and analyze and report on it so that it’s actually useful.

Unleash live’s Autofly was created to address these challenges, providing various benefits to help inspectors do their job. See all the ways that Autofly is helping inspectors in the energy industry.

What Is Autofly?

Autofly is an app made by Unleash live that allows inspectors to do remote inspections and collaborate with other stakeholders in the inspection process by centralizing everything they do in one place.

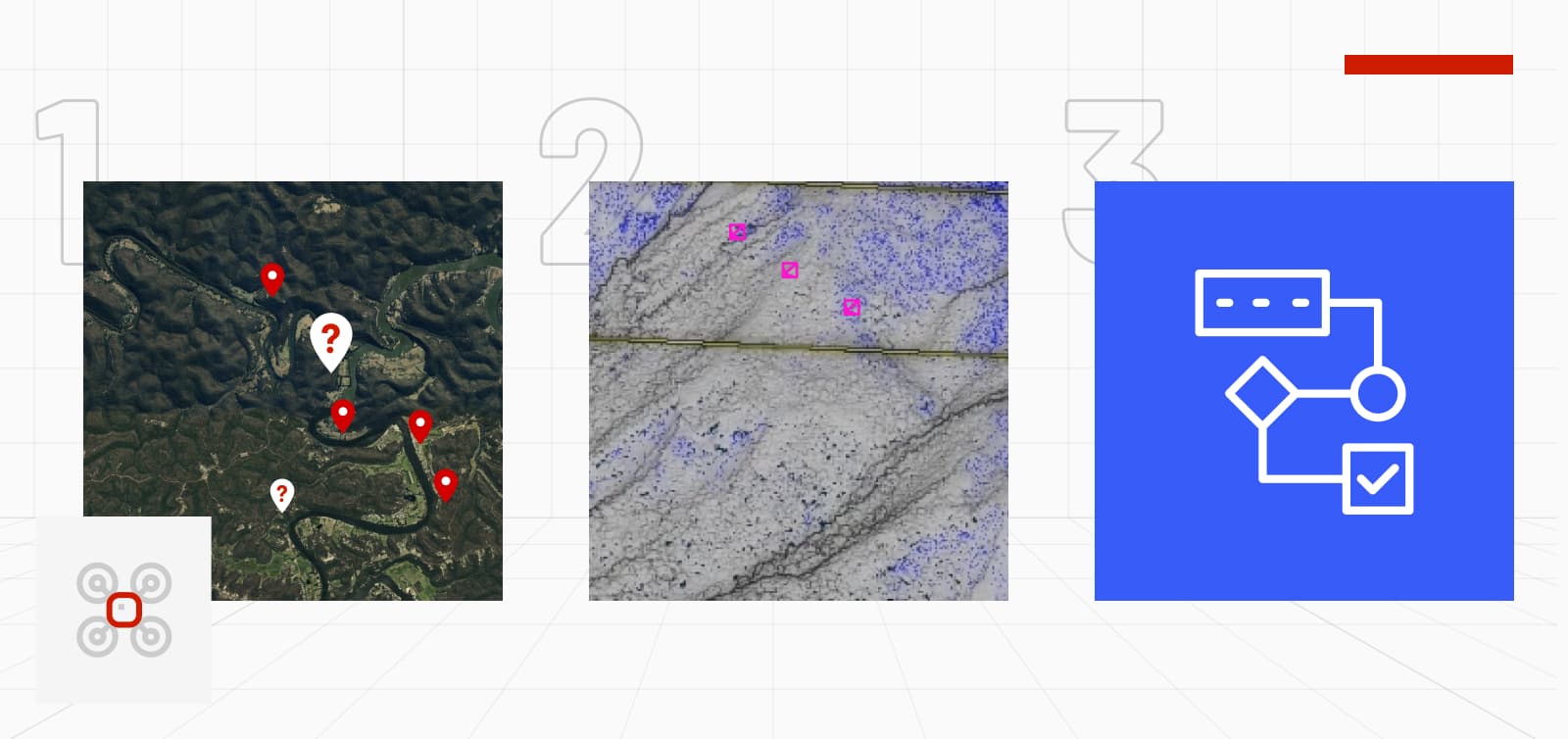

Unleash live's Autofly and remote cockpit are used for inspection planning, operation and management

The app was designed to meet the demands of all the phases of the inspection process, from planning to data collection to analysis and the production of a final report. On the operations side, Autofly lets you:

-

Manage inspection team work orders better

-

Live stream your inspections

-

Remotely control both the drone’s gimbal and the drone itself during inspections in real time

-

Collaborate on drone missions with Autofly pin-drop

-

Optimize flight planning by importing JSON and KML files

-

Implement advanced security measures using role-based access controls

-

Apply AI analysis to automatically surface potential defects in inspection footage, helping streamline the inspection process after data collection

And on the storage and management side, Autofly lets you:

-

Sync orthomap and KML layers to support inspection, emergency response, and search and rescue missions

-

Auto-upload the data your drones and cameras collect during inspections

-

Easily store and manage your data, with the ability to implement filters and review data through tags and other features to make it as useful as possible

-

Create the outputs you need from your data, including 3D models, orthomosaics, and virtual reality environments

Autofly is an Android app that lets you connect your smartphone or DJI Smart Controller to your Unleash live account. It currently works with drones in the DJI Mavic series, the DJI Phantom series, and the DJI Matrice series, including support for the M3, M3T, the M30, and the M300 and M350.

Learn more about Autofly now, or keep reading to see all the benefits it provides for inspections in the energy sector.

How Autofly Is Changing the Game for Energy Inspections

Unleash live’s one-connected platform is the one location for centralizing inspection operations. Autofly allows teams to conduct remote inspections, get desired outputs, like point clouds and orthomosaics, leverage AI apps to streamline inspection analysis and collaborate throughout the process. Inspections in the energy sector can be expensive and time-consuming since they often require either a team of people to climb power lines or use costly equipment like helicopters. Further, a limited number of experts available to complete these inspections can slow the process since each expert can only be in one place.

But Autofly is helping change this paradigm, allowing experts to be involved in several inspections a day regardless of where they occur by doing them remotely, making the entire process faster and less expensive.

There are five ways that Autofly is helping inspectors in the energy industry radically improve their operations:

1. Remote inspections

Using Autofly, inspectors can access Unleash live’s low-latency, high-definition live streaming, allowing experts and other stakeholders to view a drone’s live feed while it’s collecting inspection data. But the remote inspection capabilities don’t stop at live streaming. Autofly also allows inspection teams to use Unleash live to control both the camera’s gimbal on the drone and the drone itself. These different levels of control allow the most experienced person on the team to be in charge, regardless of their physical location.

Live streaming and remote inspections aren’t limited to a single drone—multiple drones can be operated from Unleash live using individual remote cockpits. And video streams aren’t limited to drones. CCTV, mobile phones, action cameras, and other robotic solutions can all be connected in Autofly for a single view of the inspection as it unfolds, with the capability to view up to four video streams simultaneously.

New updates to Autofly allow you to plan your work orders and drone missions using JSON and KML imports. These imports give you greater flexibility and ease of planning, letting you quickly create, modify, and execute mission plans within Autofly.

2. Enabling Collaboration

Autofly makes it easy for multiple stakeholders to collaborate with each other, both within departments and externally.

Here are all the ways Autofly supports collaboration:

-

Mission planning. Autofly allows multiple team members to plan and execute missions locally and remotely, making it easy to work together regardless of location.

-

Live sharing. Share your drone’s live stream in a private feed that can be accessed by anyone you choose.

-

Include experts. Ensure you get the data you need the first time you’re on site by including experts remotely, either in data collection or in operating the drone itself, leveraging all the expertise available regardless of where the inspection is conducted.

-

Organization. By making it easy to store, share, review, and annotate live-streamed inspection footage, stakeholders can work with each other with less friction.

-

Pin drop. Drone pilots can drop pins on a map to mark points of interest during flight missions, enhancing real-time collaboration between pilots, the command center, and field crews.

3. Simple Data Storage and Management

Autofly allows you to auto-upload footage and still images as they are collected, ensuring you never lose any footage.

Media from drone flights is automatically sync'ed from the field

Auto-uploads make it easy for remote team members to immediately access inspection footage, allowing them to review it while those on site are still in place. This quick availability of inspection data means experts can ask for more data to be collected without a delay in the request, saving hours or even days of time from the need to return to the site.

Once in the platform, your data can be filtered and reviewed through tags, components, faults, or visualized geospatially for a rapid overview of asset condition.

4. AI Analysis

Autofly doesn’t just store inspection data. It also helps you analyze it to find potential defects. Using one of our many AI apps, you can automatically analyze inspection footage of power lines, boilers, or any other asset you choose. These apps help inspectors reduce the manual labor of reviewing footage for defects, speeding the process to identify the areas that may require further investigation.

The results of AI analysis can be viewed as an overlay on your images and footage. This analysis can also be applied to footage in real-time, as it’s live-streamed, helping inspectors to see where there may be defects while data is still being collected.

The AI tools you can access through Autofly don’t just provide analysis—they can also be used to generate reports, and their findings can be viewed in a customizable insights dashboard.

5. Get the Outputs You Need

Autofly allows you to turn your inspection data into all of the outputs you need, including:

- 2D models

- 3D mesh models

- Orthomosaic maps

- Point clouds

- KML layers*

- Immersive virtual reality environments

Remote Cockpit and Autofly allow for two-way control and communication of drone operations in the field

New updates to Autofly allow you to sync Orthomaps and KML layers, helping you get more out of your outputs to support your inspection work. Syncing Orthomaps as a background map allows you to create a comprehensive and accurate view of the asset you’re inspecting and the surrounding area. Syncing KML layers allows you to identify areas of interest and task drones directly from the command center.

*Note: KML layers allow you to specify a set of features, such as images, place markers, or textual descriptions, for display in a viewing browser like Google Earth or Google Maps. KML stands for Keyhole Markup Language.

Learn more about how Autofly can help improve your inspection workflow now.