How Computer Vision is Boosting the Mining Industry’s Productivity

Computer vision is transforming the way businesses operate. With the rapid deployment of state-of-the-art A.I. technologies, businesses and organizations receive more actionable data and insights than ever, driving down their costs and enabling a safer and more productive work environment.

Computer vision applications

Over the past ten years, computer vision applications have multiplied at breakneck speed. As a result, businesses are already making significant investments in AI-driven technologies, from sophisticated industrial and governmental institutions to commerce technology and medical applications.

The international market for computer vision technologies is anticipated to develop at a compound annual growth of 7.6% to $19.1 billion between 2020 and 2027. This is due to the expenditure speed and immediate advantages computer vision applications provide.

The use cases for A.I. cover a range of scenarios, though some industries have found massive benefits in using A.I. to address economic aspects and worker safety. A prime example of where computer vision is revolutionizing an industry is in the mining & metals sector.

Computer vision applications in the mining industry

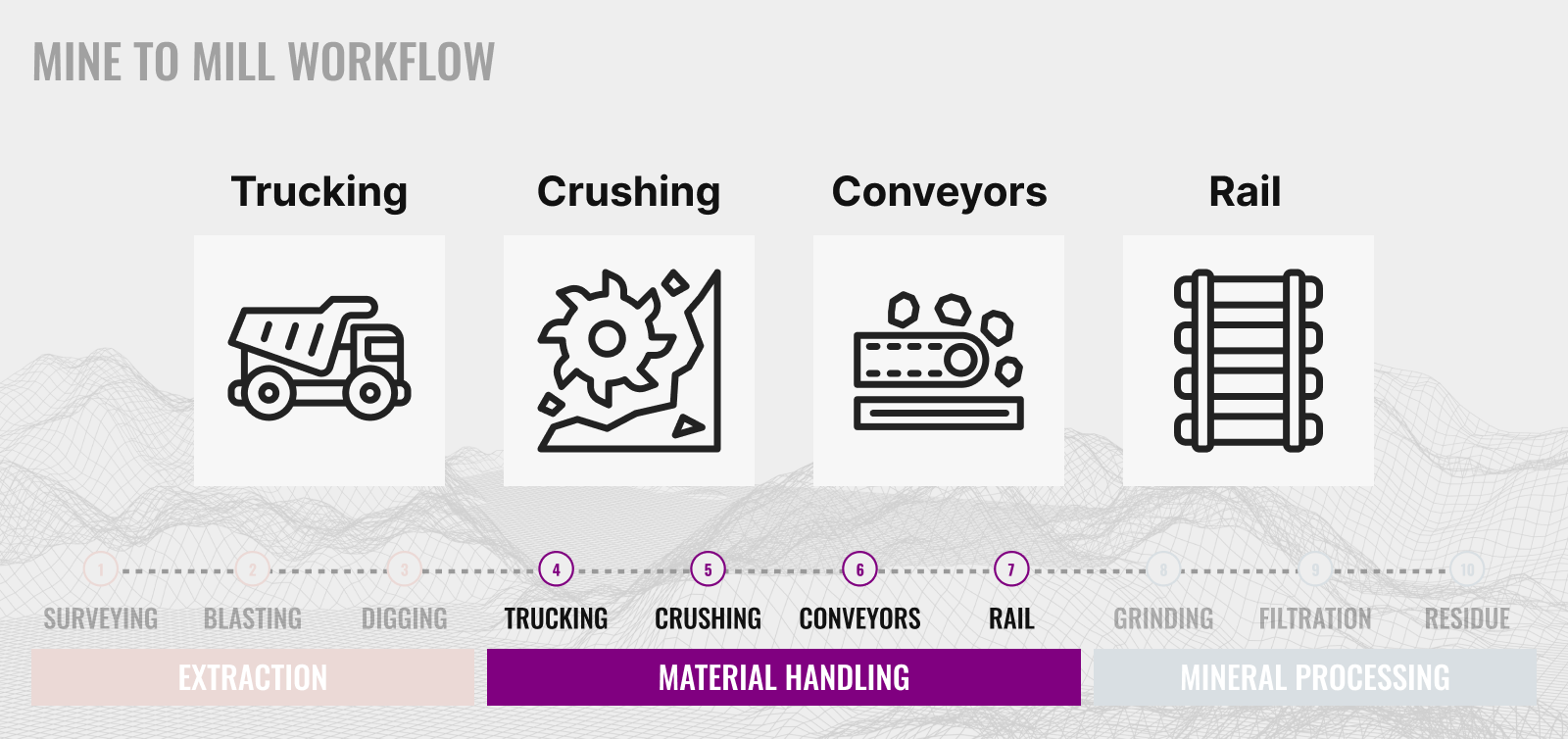

Mining, drills, and blasting are often needed for underground and surface operations in pits and subsurface quarrying. In addition, large rocks produced by mine-to-mill processes typically need to be crushed and ground down to a smaller size. Rocks are delivered via conveyor belts to grinding equipment before entering the mills, where they are subsequently crushed in size, utilizing jaws and conical crushers. Physical sizing is typically carried out during this stage to gather quantitative results on the size and distribution of stones.

This task is crucial since ore preparations are the energy-intensive step in the process, and pausing because of backlogging (a material clog) could result in hours of stoppage for the entire operation.

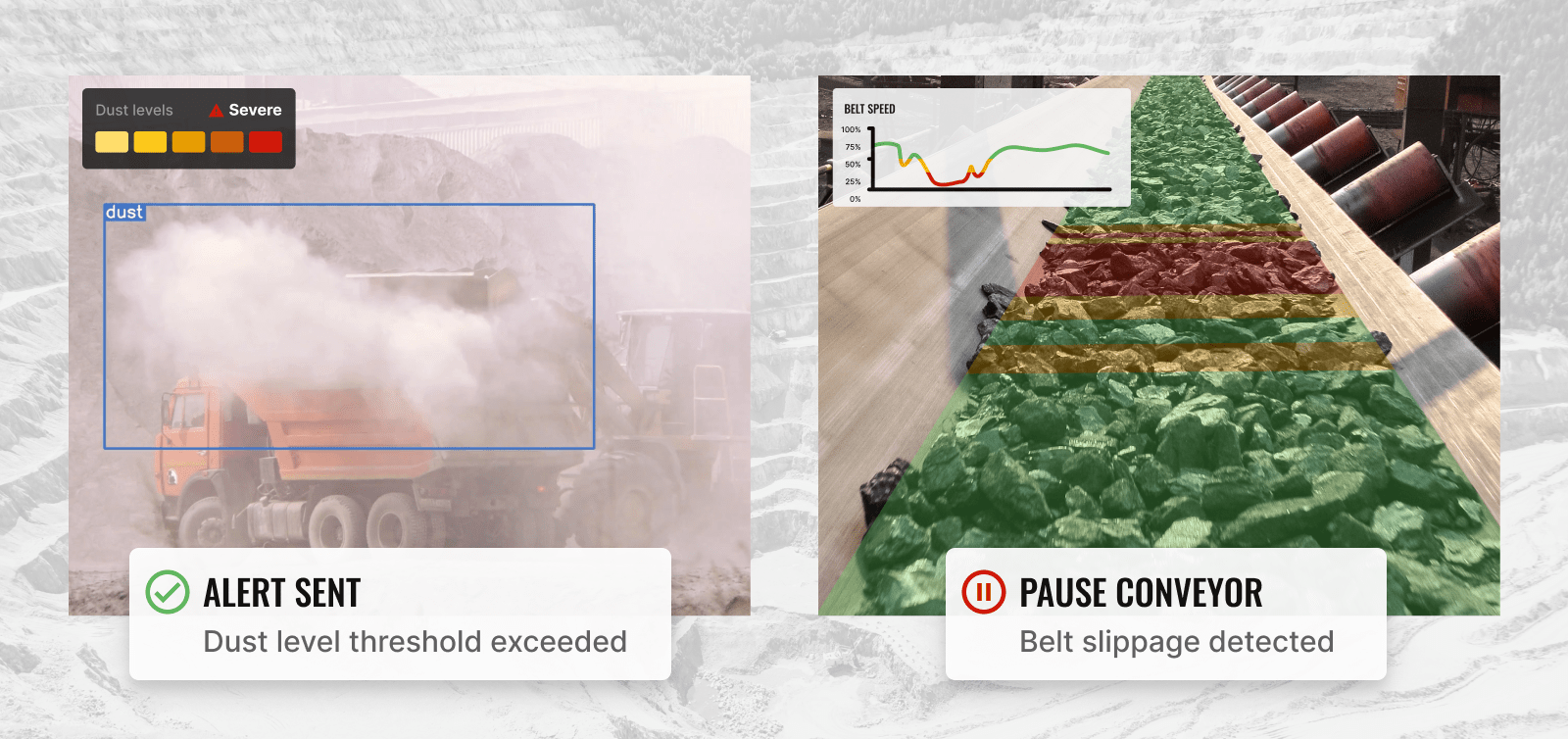

This is where computer vision steps in. Computer vision techniques can identify big impurities in the ore streams that could be hazardous to the technical process's flow. Following the detection and classification of massive objects, intelligent vision using video capture can alert operators and, if needed, halt production to address issues.

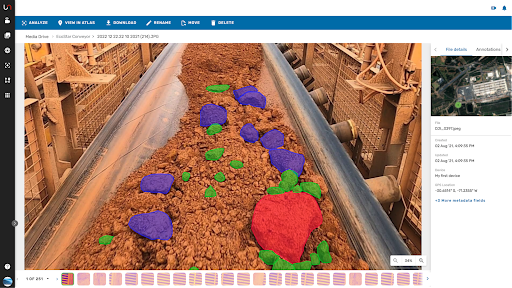

Large rocks are detected as part of conveyor belt monitoring with computer vision in Unleash live

Computer vision is finding its place in the whole mining lifecycle. From pre and post-blast clearances by identifying personnel in restricted areas, through to conveyor analytics, where a camera is installed to measure rock size and shape in real-time. Operation teams now have access to data to make informed decisions quickly with confidence whilst limiting the need for personnel to enter areas of extreme risk.

Why has AI become so important to mining companies?

All the stages of mine-to-mill have inherent risks. The mining industry is an extremely hostile place for both people and machines. Workplace injuries cost mining organizations vast amounts of money in compensation, downtime, and retraining replacement staff. Additionally, mining companies experience 1.2 million hours of unforeseen machinery downtime annually, equating to 23 hours per month on average. The cost estimate attributed to this downtime is roughly $187,500/hour, or $225 billion annually.

Increased safety and reduced downtime are hugely important to business operators. Conveyor analytics have proven to remove steps from the mine-to-mill lifecycle and grant deep insight into equipment health. Understanding each process digitally enables operations to shorten inspection times, reduce safety hazards, boost operator output, and foresee downtime events before they occur. With all these considered, mines start to see improved cost-effectiveness.

— Daniel Keys Moran

Unleash live has learned to understand the needs of this sector by building robust A.I. solutions with a purpose. Using already installed camera systems, computer vision can be deployed rapidly at scale with every growing use case.

How to harness computer vision

In the past, computer vision could only perform a few tasks, required a great deal of collected data, and required many labor hours to input and analyze data. Moreover, the process was highly sophisticated, deterring organizations from implementing this software.

Fast forward to today: modern intelligent vision algorithms have high levels of accuracy, and time and ease of implementation have been addressed. Now a plug-and-play solution, businesses can use their pre-existing hardware to connect with software solutions that keep track of all their assets with computer vision.

Unleash live has developed a platform for storing and overviewing all ingested data in one ‘hub.’Geolocation and live dashboards allow ease of use around the globe. Additionally, user roles allow team members direct access to their relevant insights, whilst business leaders are provided a complete overview of asset health and operations accompanied by in-depth reporting. It’s as simple as integrating software into their tech stack.

Computer vision is no longer a future technology; it is being rolled out today with huge economic advantages. If you’d like to learn more about computer vision in mining or any other industry, contact the Unleash live team to learn how to gain faster and more accurate insights to realize increased ROI and team safety.