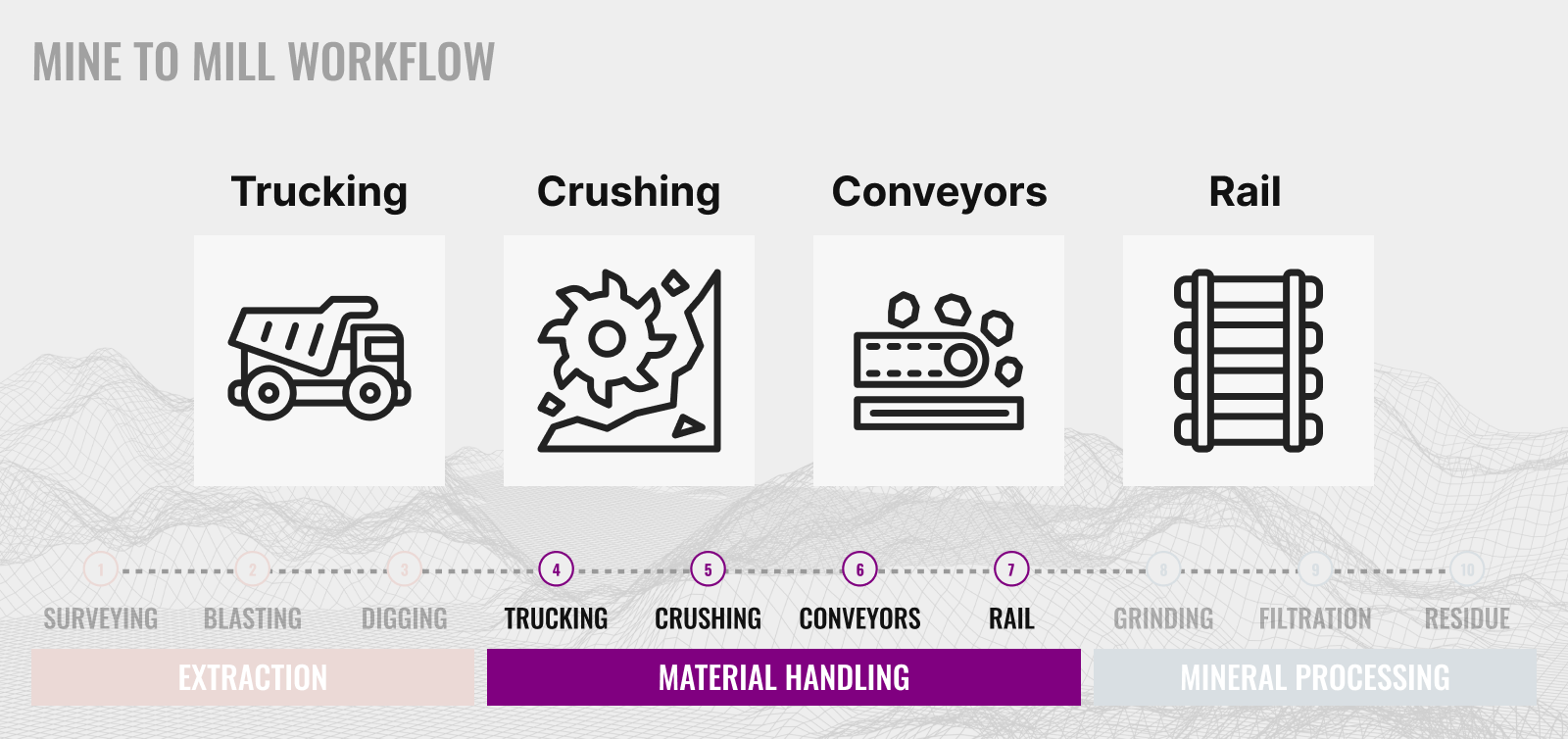

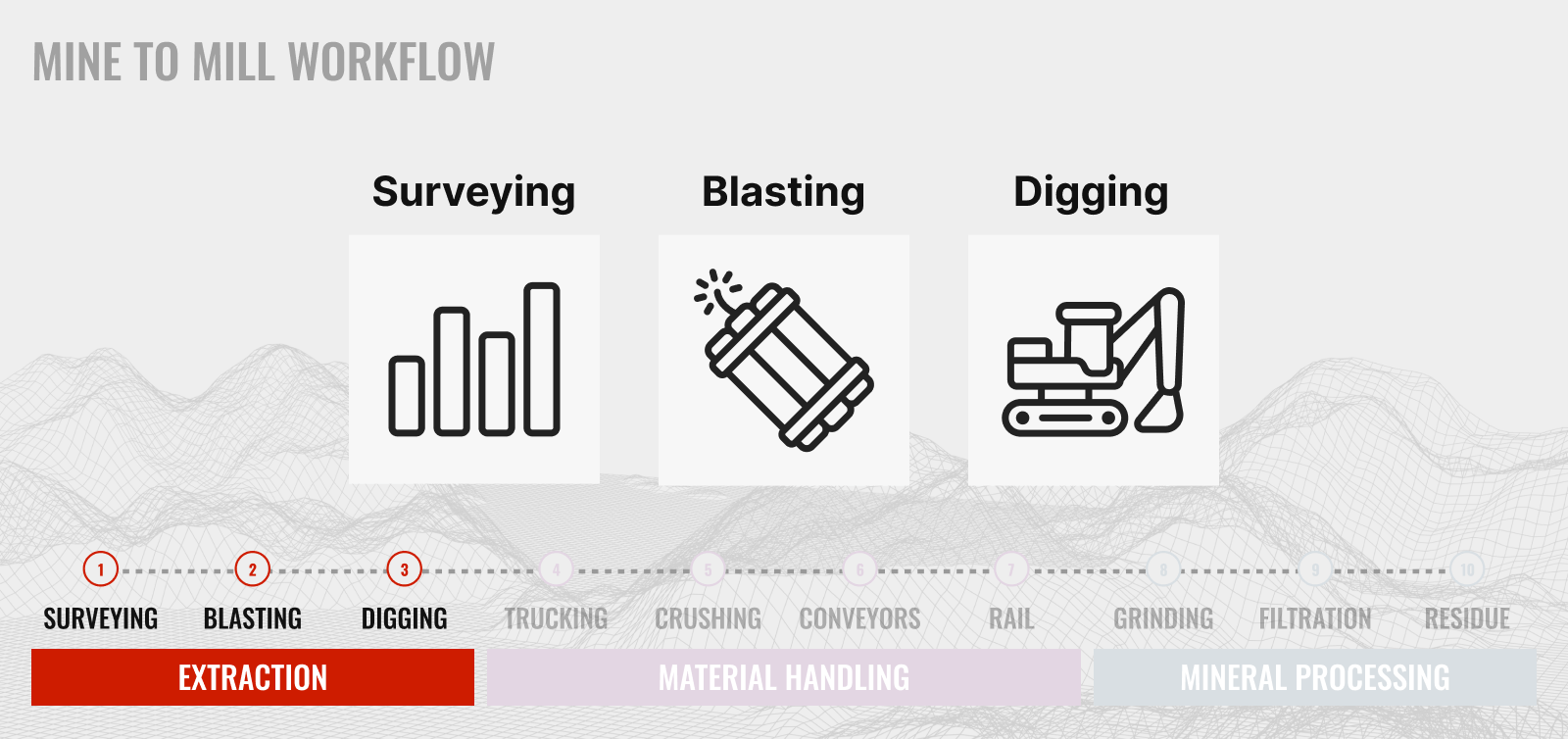

Digitizing Mine to Mill Workflows Series - Part 2 Material Handling

Workflow - Computer Vision for Improved Safety & Productivity

Introducing digital transformation for the entire mine to mill workflow. Unleash live's three part series offers valuable insights into how we facilitate operational efficiency and safety within the resources industry.

Mine to Mill Workflow and Use Case Identification

Part 2 Material Handling: Trucking, Crushing, Conveyors & Rail

Discover how Unleash live's tailored approach can reduce downtime, improve safety and increase throughput. Explore a range of use cases for computer vision with drones or IP cameras in part 2, 'Material Handling', including; crusher analytics, cart monitoring, linear pipeline, conveyor and rail performance monitoring, rail yard logistics, hot roller detection, stockpile volume measurement, as well as over and under stocking detection.

Streamline operations, improve asset performance and ensure the safety and sustainability of your mining endeavors in a very short period of time.

Blogs

Smart Volume Measurement with Unleash live

Unleash live offers 2D and 3D AI modeling, where you can create rich models from drone assets, including stockpile volumes and areas. Our Smart Volume estimator feature calculates accurate estimates for various materials and volumes.

Intelligent vision & remote drone operations connected via Starlink

Unleash live has successfully connected and navigated drones in real-time via Starlink connectivity, enabling detailed and safer remote inspections of assets without the need for travel.

Case Studies

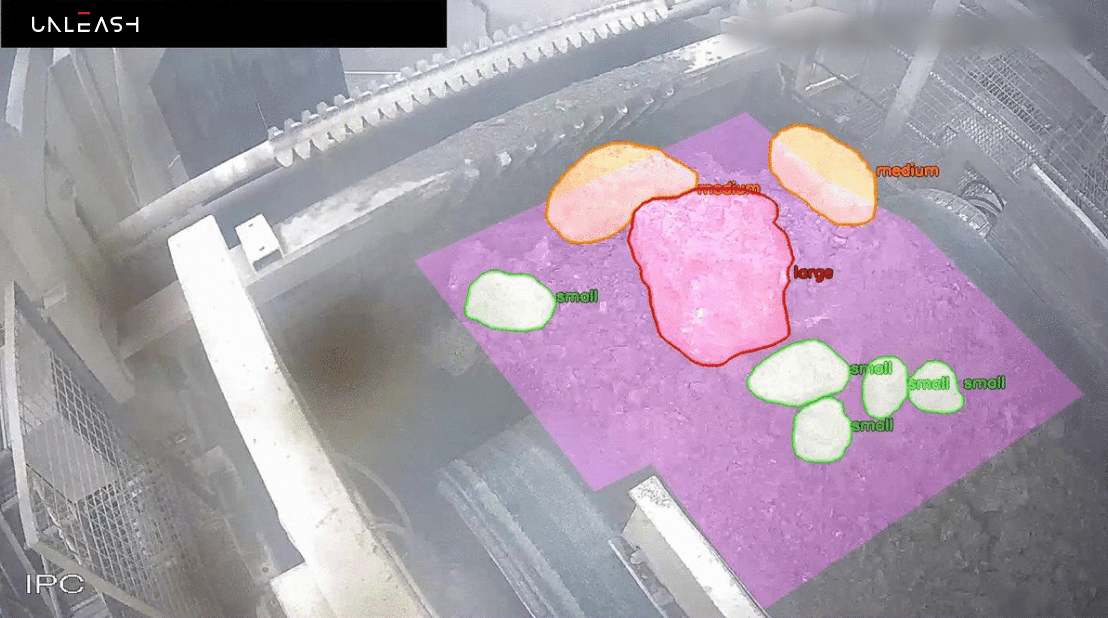

Automated Conveyor AI Analytics detecting oversized rocks

Crusher Insights

Reduced the rate of crusher failure and improve operations by implementing an automated solution to detect oversized rocks that cause machine failure on conveyor belts.

1 M+

Saved in costs

4 months

Wait time eliminated for conveyor belt replacement

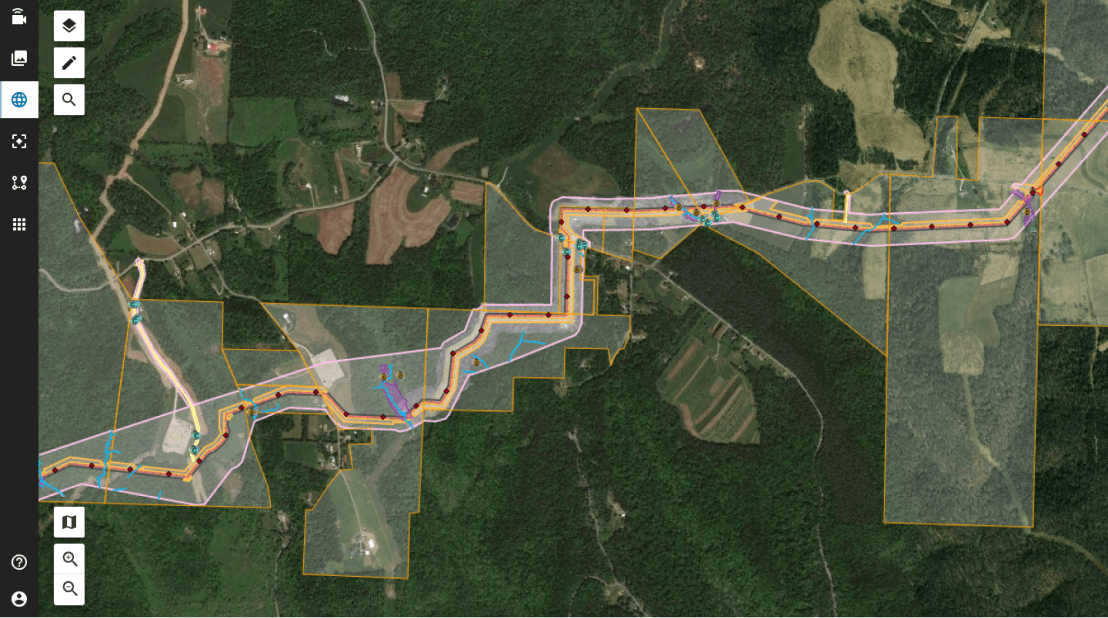

Operational Awareness with Fusion Atlas on Unleash live

Pipeline Inspection

Conducted efficient inspections with real-time collaboration, enabled by live streaming and building 2D Orthomosaics and 3D Point clouds.

4X

Increase in efficiency

3X

Reduction in cost

Filter Press AI providing valuable insights to reduce overall downtime

Filter Press

Recommended and deployed CCTV cameras and AI to provide constant monitoring, alerting and performance analytics for the filter press asset.

1 M+

Reduced consumable cost and asset downtime

4 months

Prevent blowouts and unplanned maintenance