Change is here. Renewable energy is taking center stage as demand for energy rises. But the real, often hidden, energy generation costs are higher than expected, reducing ROI and impacting investors, asset owners, and the end consumers. By automating visual inspections with computer vision, the energy sector is well placed to turn things around by saving costs, creating safer environments for workers, and extending the life of assets.

McKinsey & Co research suggests global fossil-fuel demand will peak between 2023 and 2025. After 2050, renewable energy is set to make up more than 57% of global energy supply. International Energy Agency’s World Energy Outlook 2022 report shows the global energy crisis can be a historic turning point towards a cleaner and more secure future, according to the International Energy Agency.

Mankind’s insatiable demand for energy rises every year. Across the globe, policy responses vary, but in many instances, they include determined efforts to accelerate clean energy investment. This means an even stronger push for renewables in the power sector and faster electrification of industrial processes, vehicles, and heating - and, therefore, more infrastructure spending on assets in the renewable energy sector, including solar farms and wind turbines. However, these assets are costly and have a limited life expectancy, which impacts energy generation and the pockets of investors, energy enterprises, and consumers.

"After 2050, renewable energy is set to make up more that 57% of global energy supply".

- Global Energy Perspective 2022, McKinsey & Co

The real costs of energy generation

More than 50% of the lifetime cost of an energy asset is contained in its operation and maintenance. This means that the actual costs are double or triple those predicted only a few years ago, and as a result, the ROI is 21% lower across the lifetime of an asset. When looking at the average numbers of what a renewable energy asset inspection costs, a “low” average of 12% of the total cost of an energy asset isn’t very low. This can easily result in hundreds of thousands of dollars in inspection costs over the asset's lifetime.

You may wonder why the ROI of solar farms or wind turbines is much lower than expected. It is most likely the result of one or a combination of three factors:

-

Helicopters, rigging equipment, roping, and cherry pickers needed for inspections are costly.

-

There are not enough experts to cover so many assets.

-

Your company performs inspections manually and infrequently.

Because of these three challenges, the data capture necessary for maintenance and improvements is inconsistent.

Download our free ebook, 'Mastering Remote Operations in the Energy Sector'

Three key benefits of automating visual inspections with computer vision and AI.

1. Operational clarity

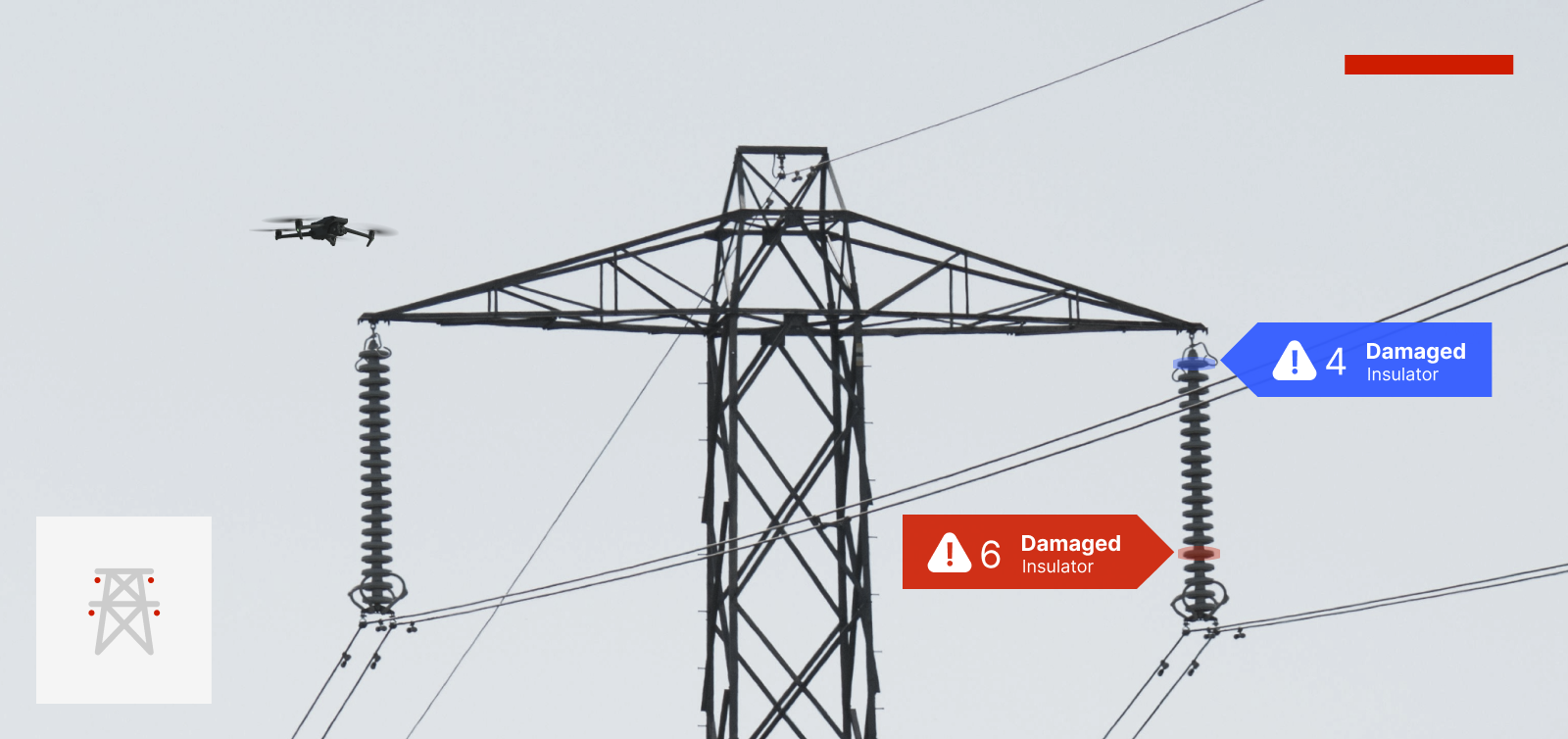

We enable organizations to measure reality by unleashing the power of visual data with real-time analytics from our computer vision AI apps and our digital platform. Having key insights into your operations quickly and remotely is invaluable. Today’s technology ensures your team can fast-track operations with remote inspections and collaboration.

You can meet your operational needs, whatever they are. Drones, smartphones, body cameras, or fixed IP cameras can all be easily connected. After you set up your device and live stream to the secure cloud platform, you’ll have access to all the asset data and immediate insights. This is perfect for experts in the office, contractors, suppliers, and the team on the ground.

2. Cost-effective inspections

Many people fear automated and high-accuracy digital inspections must be incredibly expensive. Not so!

Putting off a smaller cost only to face a much larger cost down the road is never a savvy financial decision. What would happen if you never got an oil change? You’ll be on the side of the road before you know it, facing a much larger repair bill than the cost of an oil change. The same financial principle applies to operating and maintaining your energy assets!

Using technology to inspect your assets remotely can avoid costly repairs and reduce outages to critical infrastructure. For one thing, most of the costs have been stripped away by moving to a cloud service model, leveraging commercially widely available cameras and drones. Plus, you will have greater transparency on the work being conducted by remote in-field colleagues while connecting all into your asset maintenance workflow.

3. Targeted actions for better ESG, OH&S, and maintenance

The benefits of improving your operational and maintenance processes extend well beyond the financial. To identify risks and growth opportunities, investors and regulators increasingly apply Environmental, Social, and Governance (ESG), Occupational Health & Safety (OH&S), and other non-financial factors as part of their analysis.

The main non-financial reasons to adopt a transparent, connected digital maintenance and operational process include improvements in:

-

Time and cost

-

Worksite operations

-

Worker safety

-

Identifying risk

-

Documentation and collaboration

-

Decision quality

As a platform, Unleash live enables the development and deployment of independent computer vision AI apps for productivity gains, cost improvements, and increased safety by delivering structured data for faster, more insights-based decision-making where previous workflow was based upon inconsistent, anecdotal, or inefficient processes. Learn how to maintain and extend the life of your energy assets with computer vision and a seamless digital workflow by reading our Mastering Remote Operations in the Energy Sector ebook.