In industries where any type of material wear and tear is a critical factor, whether in production lines, processing facilities or field operations, maintaining the longevity of components is essential for cost-effective, efficient operations. Constant monitoring of materials, such as filter cloths, conveyor belts and other production line equipment, helps identify damage early and allows for timely intervention, reducing downtime and costly repairs.

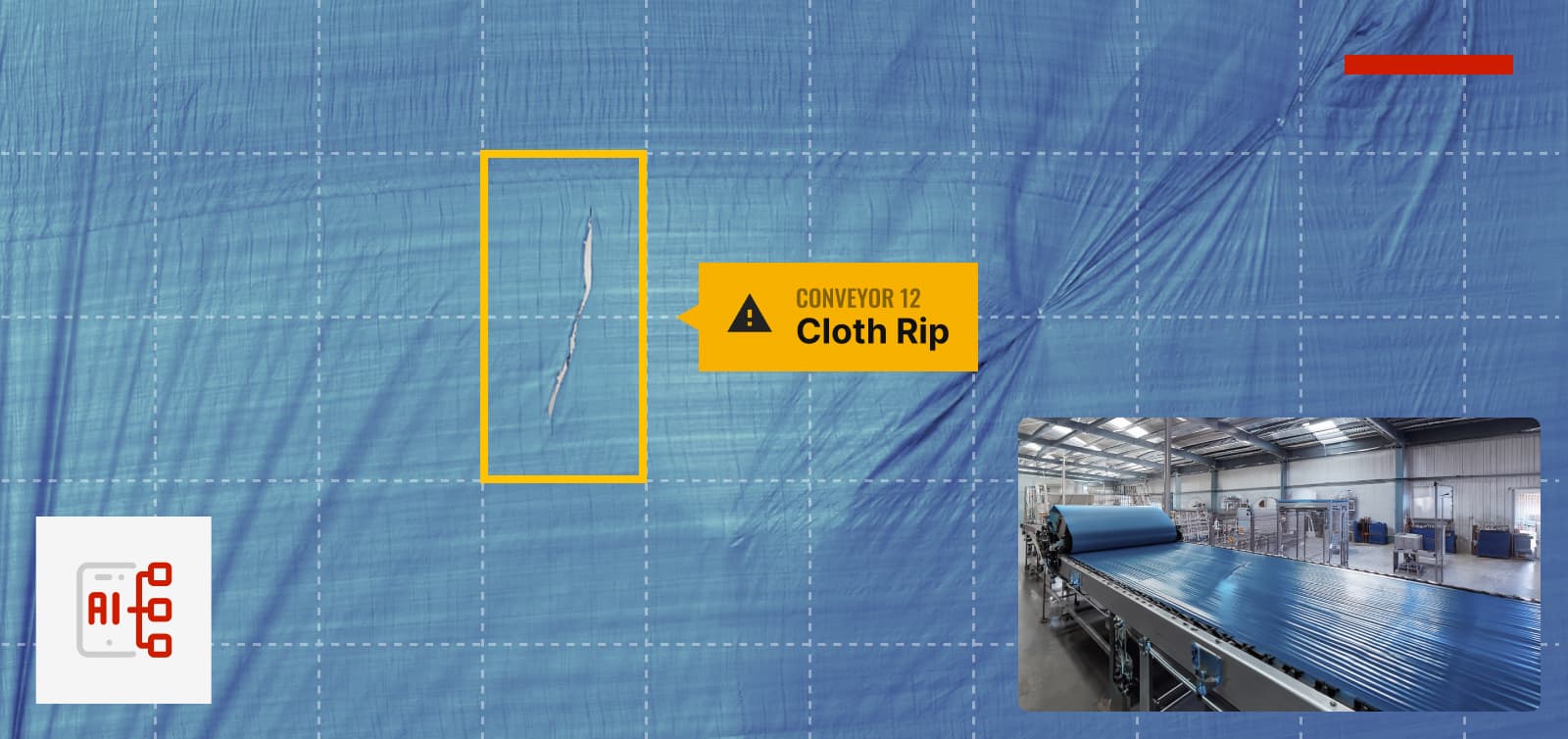

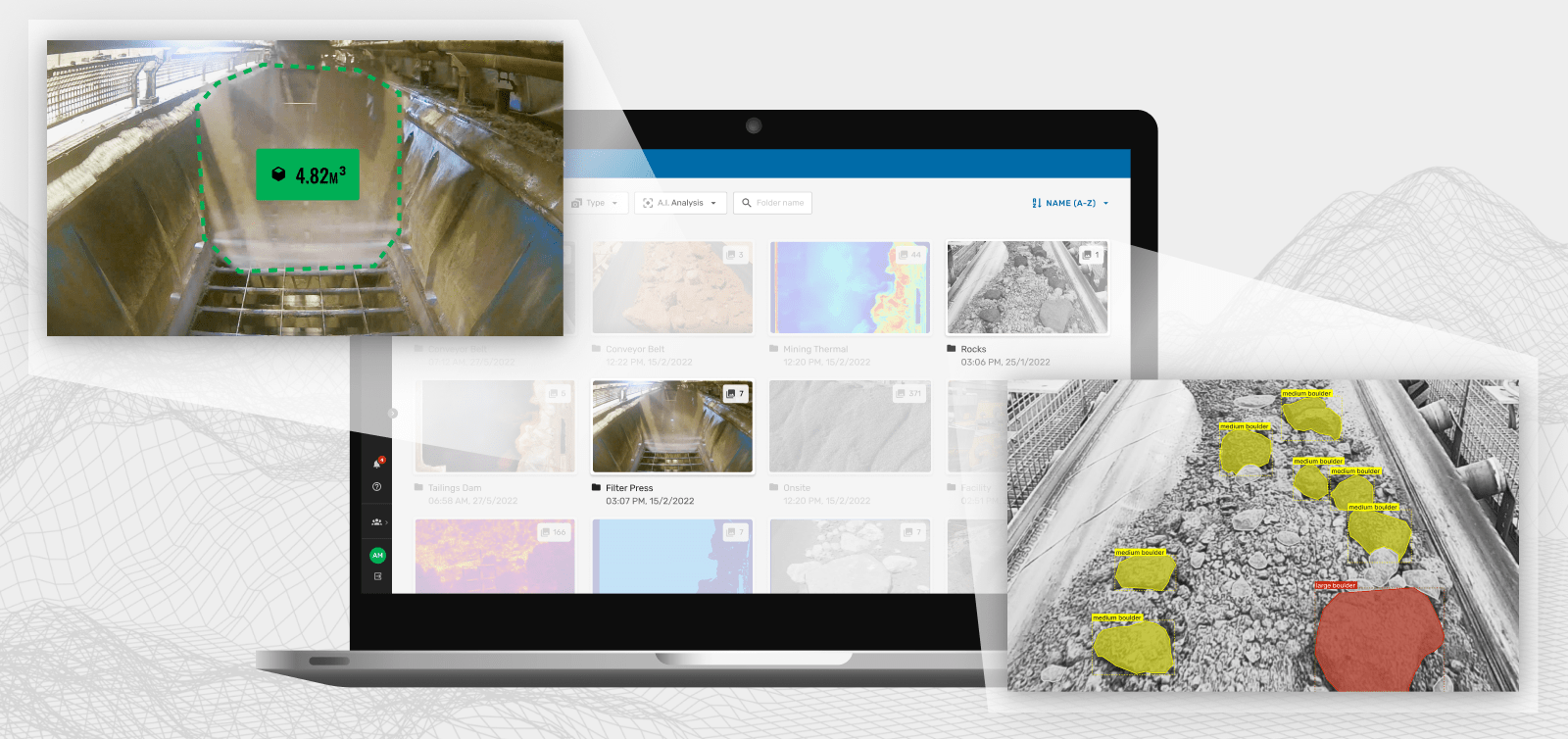

To address this need, Unleash live has developed the Material Damage Detection AI App (MDD), an AI-driven solution that provides real-time video analytics for monitoring material health. This solution automates inspections, making it possible to remotely monitor assets for signs of damage like holes, cracks or wear, which would otherwise require manual inspections, sometimes coming at a very high safety risk.

How Material Damage Detection Elevates Operational Efficiency

- Increased Safety for Personnel

Manual inspections often involve close interaction with heavy machinery, exposing staff to potential safety risks. With the MDD AI App, operators can rely on automated, remote inspections, reducing the need for physical proximity to operating machinery and thereby enhancing safety. - Reduced Operational Costs and Minimized Downtime

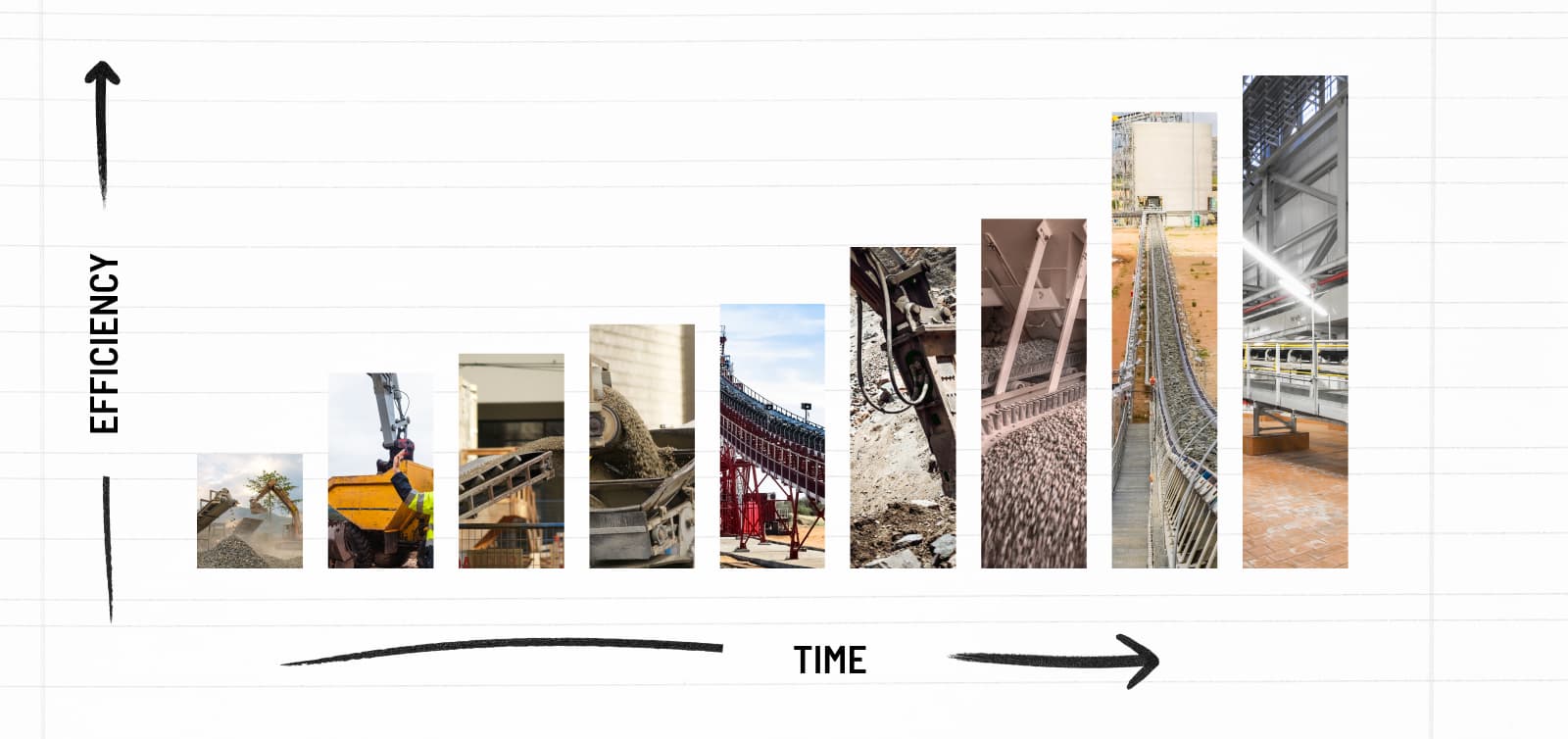

Manual inspections are not only labor-intensive but also interrupt operations, creating periods of downtime. With AI-driven video monitoring, teams can run inspections continuously without halting production. This proactive approach identifies potential issues as they arise, preventing minor wear from evolving into significant, costly damage. - Extended Asset Life

By catching small issues early, the app supports proactive maintenance, which in turn reduces wear and maximizes asset productivity. This early intervention helps extend the life of materials and equipment, reducing the frequency of replacements and promoting cost savings. - Predictive and Proactive Asset Management

The AI app’s continuous monitoring capabilities enable operators to manage assets more effectively by detecting wear patterns and predicting maintenance needs. This data-driven insight enables more strategic decision-making around maintenance schedules and resource allocation.

Application Spotlight - Filter Cloth Hole Detection in Mining

A prime example of how the MDD AI App can improve industry-specific operations is in mining, particularly in filter press operations. Filter cloths are essential in mineral processing, yet they are vulnerable to wear. Even minor holes in the filter cloth can lead to blowouts, damaging plates and interrupting production.

With Unleash live’s MDD AI app, mining operators can now automate the detection of holes and wear in filter press cloths, avoiding manual inspections that often require staff to use torches and other equipment to inspect cloths up-close. This automation enhances safety, as workers spend less time near heavy machinery and reduces operational disruptions, as inspections can now be conducted remotely and continuously.

Additionally, the app’s predictive insights on cloth wear help optimize maintenance schedules and extend the life of equipment, further supporting production and minimizing costs.

How Material Damage Detection Works

The MDD AI App integrates seamlessly with existing camera systems, continuously monitoring production lines and asset surfaces for signs of wear or damage. The Machine Learning AI software scans video feeds to identify unusual wear patterns or defects and sends real-time alerts to operators when potential issues arise. This immediate response allows teams to address problems before they become serious, preventing unnecessary equipment strain and extending the life of essential materials.

The app also logs historical data on wear patterns, helping teams predict future maintenance needs and make data-backed decisions on resource allocation.

Transforming Operations with AI-Powered Inspections

Unleash live's MDD AI App is part of a broader vision to enable safer, more efficient and cost-effective operations across sectors. As industries embrace digital transformation, AI-driven video inspections are becoming invaluable tools in mitigating risk, reducing costs and optimizing workflows.

Whether in mining, manufacturing or processing, investing in tools like the MDD AI App represents a proactive step toward more efficient and future-focused operations. With Unleash live’s video analytics platform, operators can automate inspections, increase productivity and maintain a safer, more productive work environment.

To learn more about how the Material Damage Detection AI App can streamline inspections in your industry, contact Unleash live today.