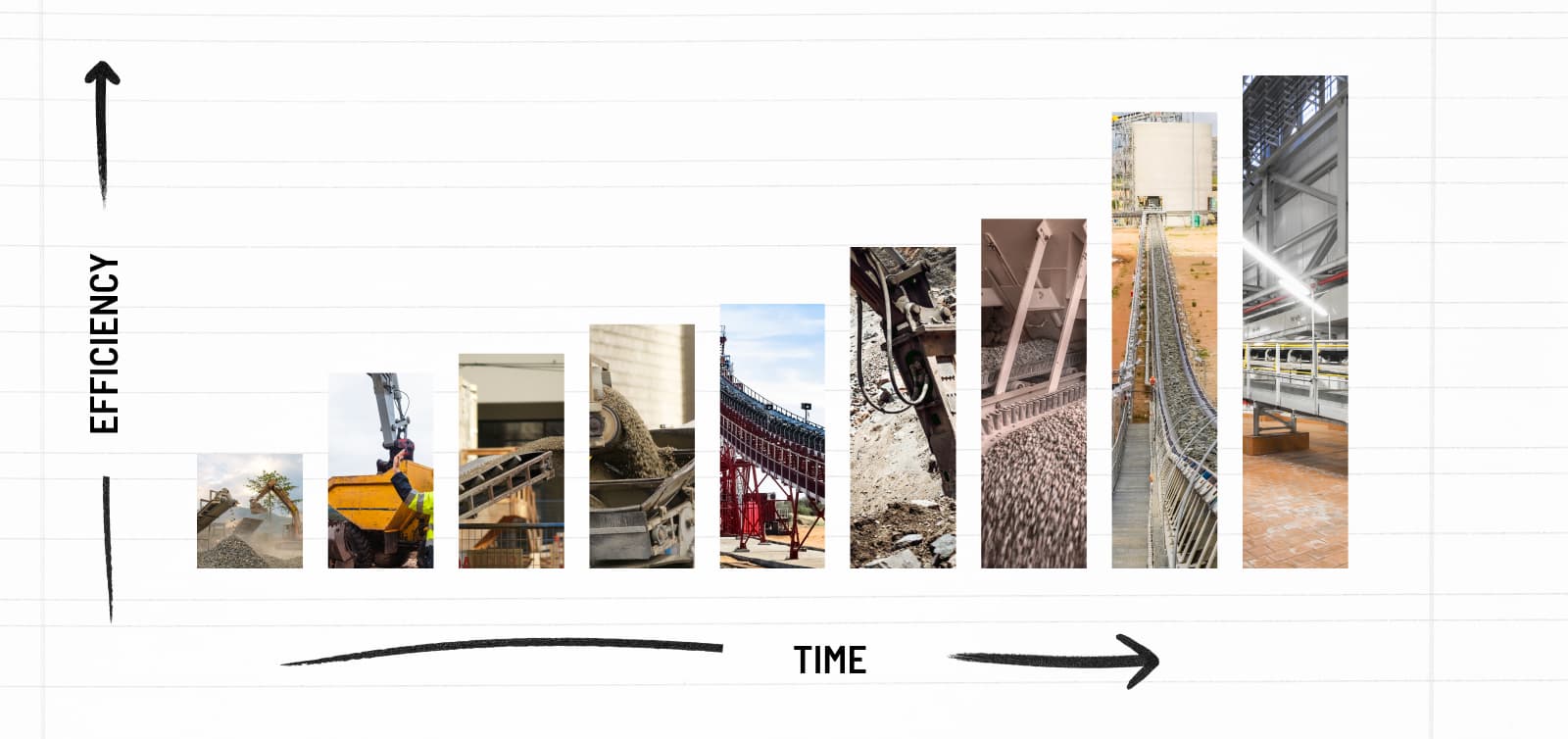

The mining industry, with its massive scale, operates like a finely tuned machine. However, maintaining efficiency in such a vast and complex environment, from upstream activities like excavation to downstream processes like mineral refinement, is no small feat. The need for compliant materials, efficient staff performance and accurate volume measurements is more crucial than ever.

Enter AI Video Analytics

By integrating AI and computer vision into mining operations, companies can achieve the real-time monitoring and automation required to maximize operational efficiency. Let's delve deeper into how AI video analytics is transforming mining, focusing on upstream and downstream production and examine real-world examples of its application.

Upstream - The Backbone of Mining Operations

Upstream mining operations involve the extraction of raw materials. This includes heavy machinery like excavators, haul trucks and crushers, all of which need to function flawlessly to avoid costly disruptions. One of the biggest challenges in upstream mining is equipment failure and unplanned downtime.

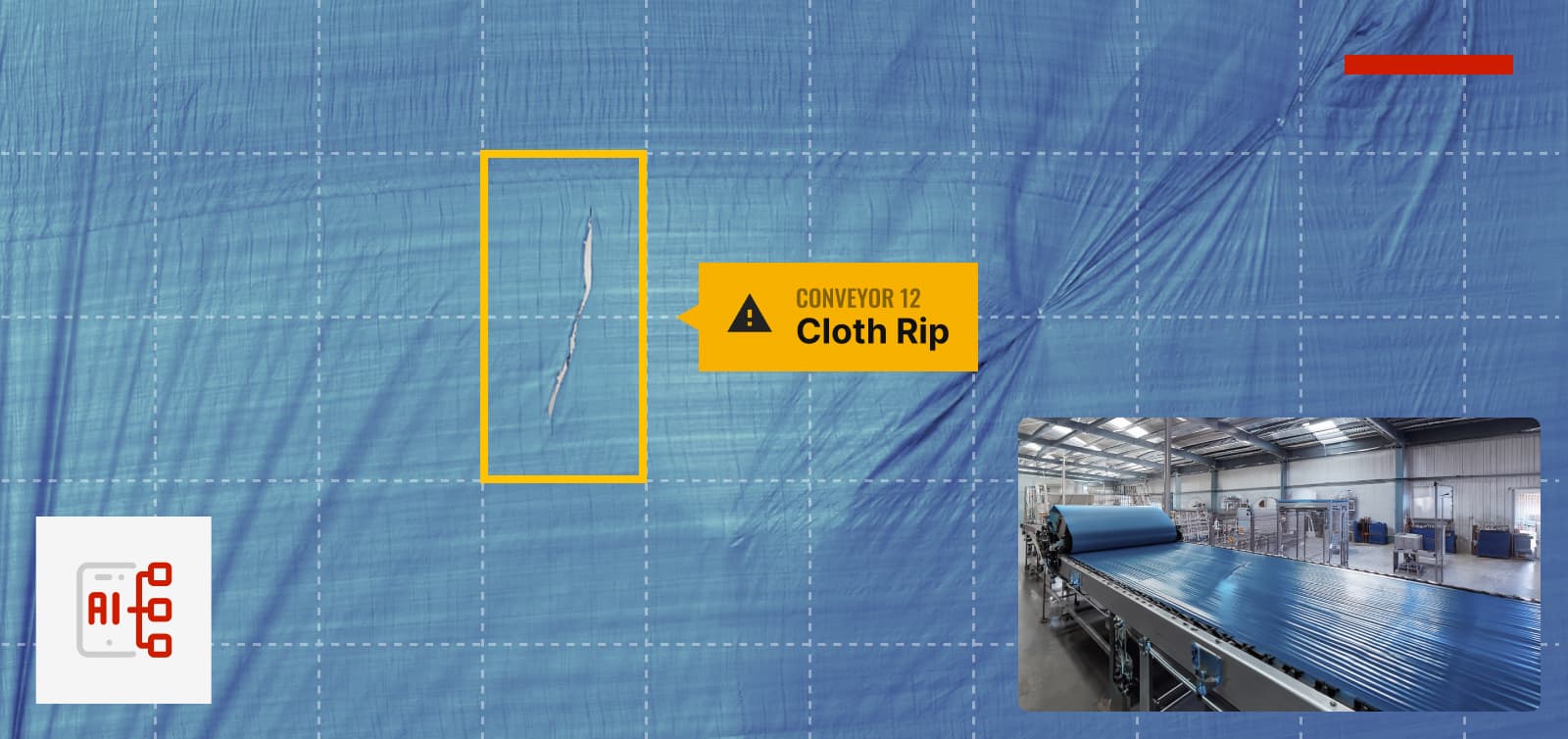

Take, for example, a boulder blocking a conveyor belt or a jammed crusher. These are common yet significant problems that can halt production entirely. With AI video analytics, sensors monitor the real-time condition of equipment. Any abnormalities, like oversized rocks on conveyor belts or faulty machinery, are detected instantly, triggering immediate alerts. This allows mining staff to take corrective action before small issues escalate into production-halting crises.

In the past, addressing such problems would have required manual inspection, leading to downtime and productivity loss. Today, Machine Learning AI computer vision can continuously monitor heavy machinery, identify early signs of wear and enable preventive maintenance. This proactive approach not only reduces equipment failure but also increases the lifespan of machinery, leading to reduced operating costs and improved efficiency.

Example: A leading mining company implemented AI-driven video analytics to monitor their haul trucks. By detecting tire wear in real-time, they reduced maintenance costs by 15% and decreased downtime, allowing them to increase productivity by over 10%.

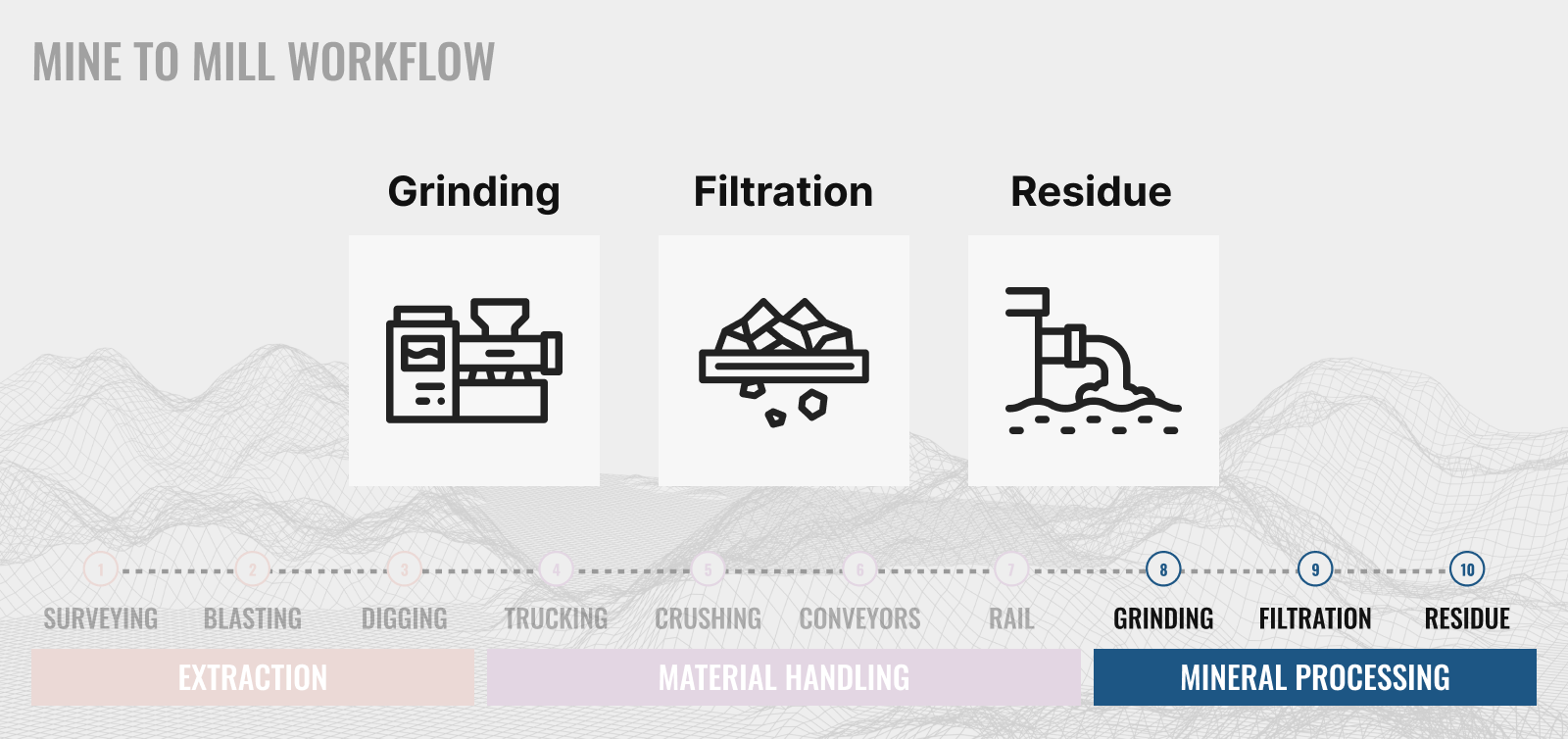

Downstream - From Mine to Refinement

In downstream production, materials extracted upstream move through various refining and processing stages. Maintaining quality and efficiency at this stage is equally critical. AI video analytics ensures that production remains compliant and efficient by providing insights into flow rates, material quality and bottleneck areas.

For instance, AI-driven systems can monitor material throughput in processing plants and optimize production to ensure it matches demand. AI can analyze the size, consistency and speed of material being transported on conveyor belts. If a production anomaly is detected, such as inconsistent material quality or flow blockages, the system immediately alerts operators to take action. This can prevent significant issues like processing plant overloads, quality degradation, or material waste.

Additionally, AI video analytics enhances compliance and safety in downstream operations. With continuous monitoring, mining companies can identify safety breaches in real-time, such as employees not wearing proper PPE (Personal Protective Equipment) or hazardous materials not being handled correctly. AI alerts management, ensuring swift action to mitigate risks, fostering a safer working environment.

Example: Unleash live stands out with its solution that harnesses the power of AI for rock detection automation. This cutting-edge solution uses existing plant cameras to monitor conveyor belts in real time, 24/7. When a rock surpassing a predefined size threshold is detected, the system immediately alerts operators, enabling them to swiftly remove it before it causes any damage. Read the full case study.

Additional business rules, logic and alerting can be set up to reduce machinery damage and downtime, such as this example detecting oversized rocks on a mining conveyor

Enhanced Compliance and Performance Monitoring

In mining, compliance is non-negotiable. Regulatory requirements often dictate how materials must be handled, processed and transported. Failure to meet these standards can lead to hefty fines, operational delays and even reputational damage. With AI, compliance can be automated and streamlined.

For example, AI systems can be programmed to monitor staff adherence to safety protocols. If workers are found without proper safety equipment, such as helmets, reflective vests, or gloves, AI alerts supervisors in real-time. This enhances both safety and accountability across the organization.

Training and Employee Performance: AI can also highlight underperforming processes or employees, providing data that allows managers to develop more targeted training programs. In this way, the entire workforce understands how their role impacts the broader production workflow.

Example: Personal Protective Equipment (PPE) is a fundamental aspect of workplace safety, yet ensuring compliance across diverse work environments can be challenging. Enter the PPE Detection AI App by Unleash live. Using state-of-the-art computer vision algorithms, this app automatically recognizes PPE items such as helmets, safety vests, masks, goggles and gloves in real-time video streams.

Download our PPE Solution Brief for more information.

AI in Predictive Maintenance: A Game-Changer for Mining

Perhaps one of the most transformative aspects of AI in mining is predictive maintenance. By using AI video analytics to monitor equipment and detect early signs of wear and tear, companies can forecast when machines are likely to fail and schedule maintenance accordingly. This minimizes unplanned downtime and maximizes asset utilization.

Example: The complex network of machinery and equipment, from excavation to material handling and mineral processing, forms the backbone of mining production. Any disruption, whether due to equipment failure or operational stoppages, can result in significant financial losses. This is where Unleash live's AI video analytics comes into play, offering real-time monitoring, early intervention and predictive maintenance to minimize costly interruptions and machinery damage. Read more.

The Path Forward - AI Video Analytics as a Mining Partner

Mining companies that incorporate AI video analytics into both upstream and downstream operations are reaping significant benefits. From improved efficiency and reduced operational costs to enhanced compliance and safety, the value of AI in mining is undeniable.

By providing real-time monitoring, predictive maintenance and comprehensive oversight of every stage of production, AI enables mining companies to stay competitive in an industry where margins are tight and efficiency is paramount. Through cutting-edge technology, mining operations are becoming smarter, safer and more sustainable.

With Unleash live, mining companies can elevate operational excellence and drive productivity to new heights, ensuring they remain competitive in a challenging and dynamic industry.

To learn more about how Unleash live’s Machine Learning AI video analytics solutions can transform your mining operations, visit our website or contact our team for more insights.