In today’s industrial landscape, predictive maintenance has emerged as a crucial strategy for enhancing operational efficiency and reducing downtime. Utilizing advanced technologies like computer vision with CCTV or machine vision cameras, industrial companies that have sophisticated and critical assets can proactively address equipment issues before they escalate into significant problems.

In many instances, vision sensors have demonstrated a significant advantage over traditional sensors. Read more here to learn about the differences between vision sensors and traditional sensors.

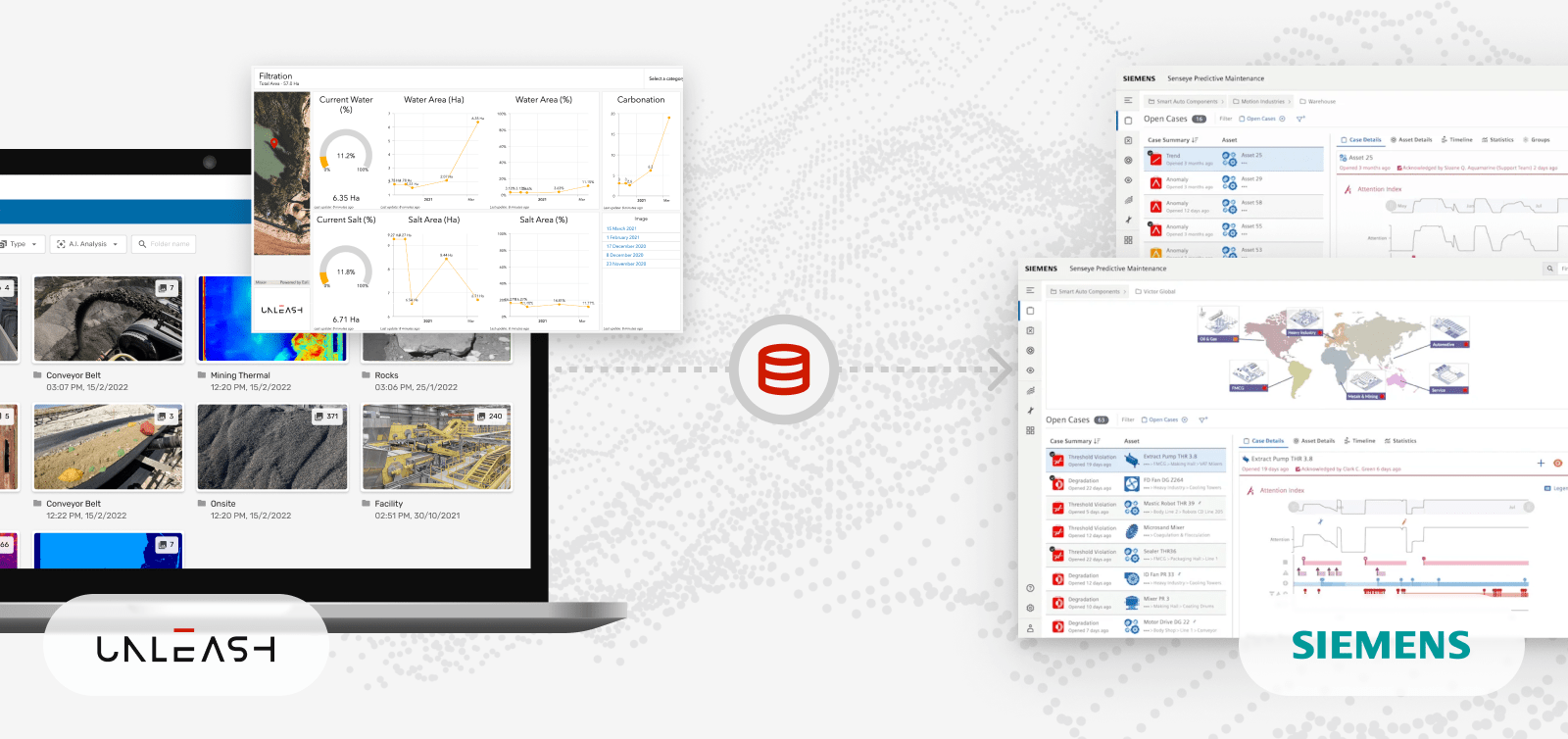

This blog however, explores the integration of vision sensor analytics data from Unleash live into Siemens’ Senseye Predictive Maintenance platform, highlighting the transformative potential of this integration.

The Role of Unleash live’s Computer Vision Solution in Predictive Maintenance

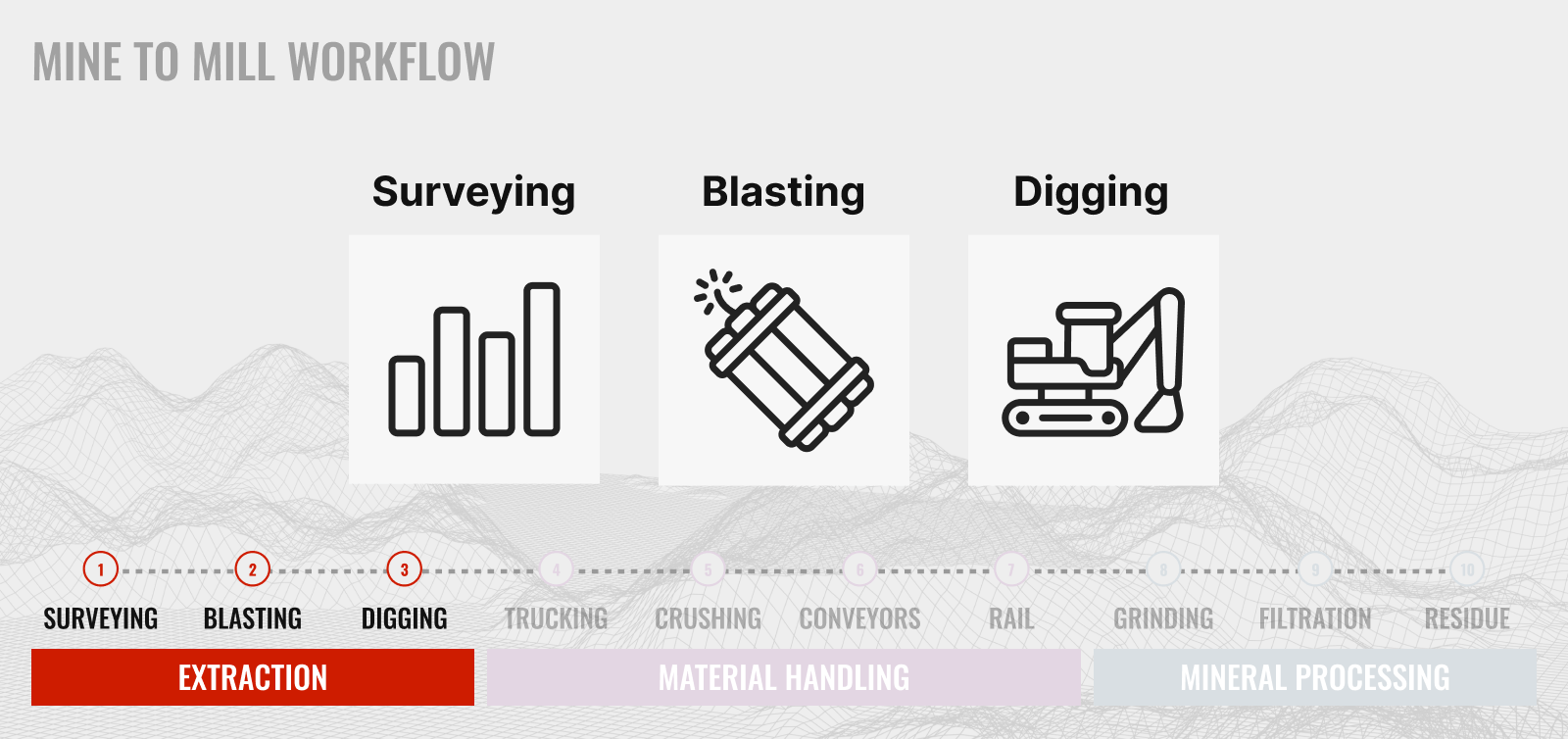

Unleash live’s Computer vision technology, leveraging CCTV or machine vision cameras, plays a pivotal role in predictive maintenance by continuously monitoring equipment and identifying potential issues in real-time. By analyzing visual data, these systems can detect anomalies such as wear and tear, misalignment and other signs of impending failure. The benefits of incorporating computer vision into predictive maintenance include:

- Early Detection of Issues: Vision systems can identify problems at an early stage, allowing maintenance teams to intervene before a minor issue becomes a major failure.

- Enhanced Accuracy: With the ability to analyze high-resolution images and videos, computer vision systems provide precise and reliable data, improving the accuracy of maintenance predictions.

- Cost Savings: By preventing unplanned downtime and extending the lifespan of equipment, companies can achieve significant cost savings.

Introducing Siemens Senseye Predictive Maintenance

Siemens Senseye Predictive Maintenance is an advanced platform that leverages artificial intelligence (AI) and machine learning (ML) to predict equipment failures and optimize maintenance schedules. The platform integrates data from various sources, including sensors and historical maintenance records, to provide actionable insights and recommendations.

Integration of Vision Sensor Analytics Data to Senseye

The integration of vision sensor analytics data generated from Unleash live platforms into Siemens Senseye marks a significant advancement in predictive maintenance capabilities. This integration allows for a more comprehensive analysis of equipment conditions by combining visual data with existing sensor data and predictive models.

Siemens' Senseye Predictive Maintenance platform in action

Key benefits of this integration include:

- Comprehensive Monitoring: By integrating visual data, Senseye can offer a more holistic view of equipment health, considering both traditional sensor data and visual indicators of wear and tear.

- Enhanced Predictive Accuracy: The additional layer of visual data improves the accuracy of predictive models, leading to more reliable maintenance recommendations.

- Streamlined Maintenance Processes: Maintenance teams can access all relevant data from a single platform, streamlining the decision-making process and reducing the time required to diagnose and address issues.

- Scalability: Because of the fact Unleash live can work with existing CCTV, the integration supports scalable deployment across multiple sites and equipment types, enabling organizations to implement predictive maintenance strategies more effectively.

Conclusion

Using cutting-edge Unleash live AI Apps, the integration of vision sensor analytics data into Siemens Senseye Predictive Maintenance represents a significant leap forward in the field of predictive maintenance. By harnessing the power of computer vision, companies can achieve more accurate predictions, reduce downtime and optimize maintenance processes. As the industrial landscape continues to evolve, such innovations will be key to maintaining competitive advantage and operational excellence.