Workflow - Computer Vision for Improved Safety & Productivity

Introducing digital transformation for the entire mine to mill workflow. Unleash live's three part series offers valuable insights into how we facilitate operational efficiency and safety within the resources industry.

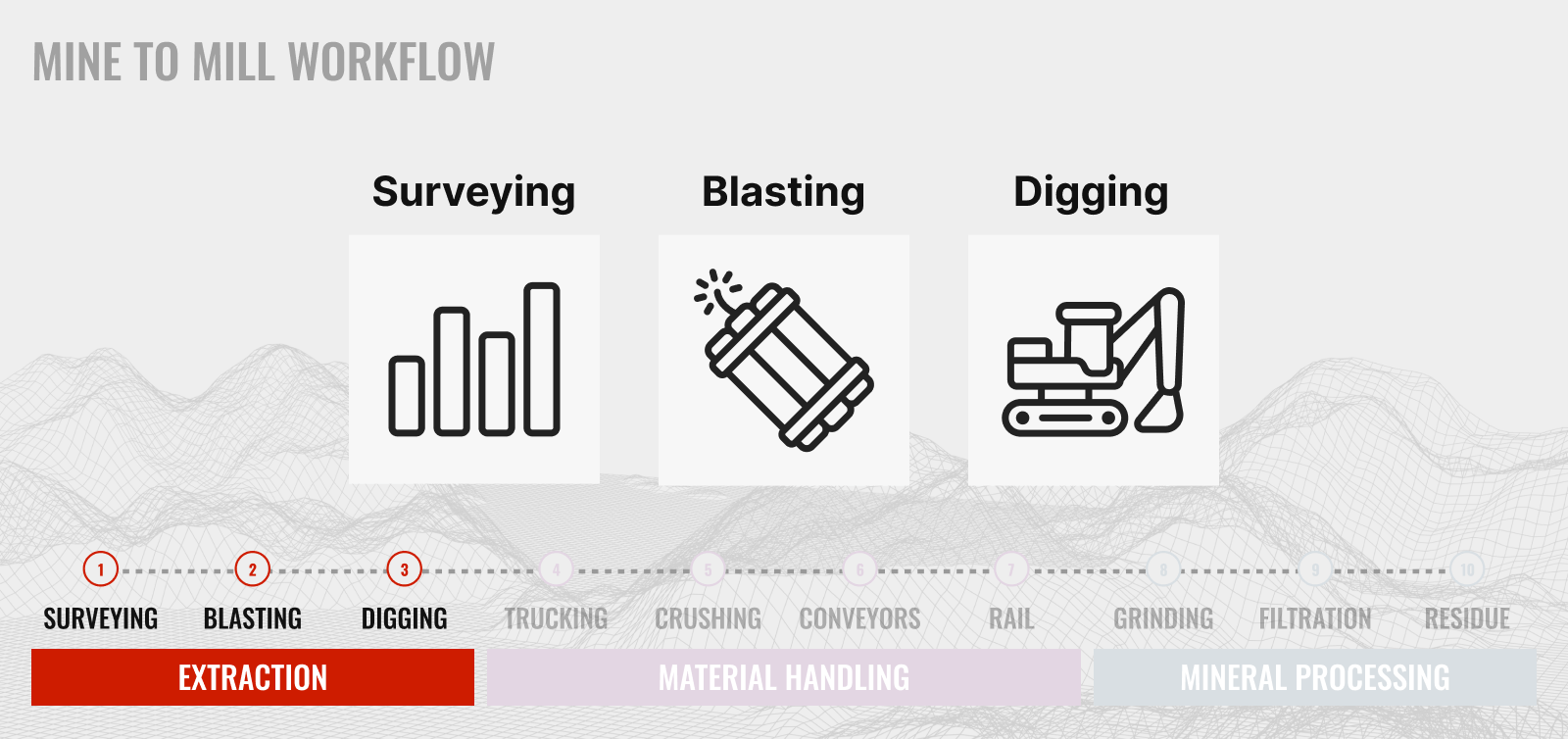

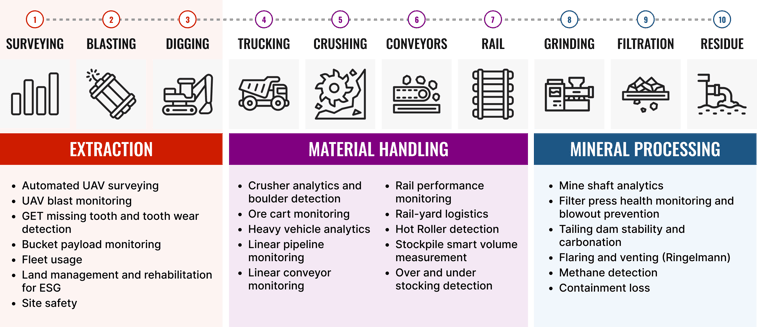

Mine to Mill Workflow and Use Case Identification

Part 1 Extraction: Surveying, Blasting & Digging

Discover how Unleash live's tailored approach can reduce downtime, improve safety and increase throughput. Explore a range of use cases for computer vision with drones or IP cameras in part 1, 'Extraction', including; surveying, perimeter monitoring, mobile plant inspections and productivity monitoring, land management, site safety and so much more.

Streamline operations, improve asset performance and ensure the safety and sustainability of your mining endeavors in a very short period of time.

Learn more

How Computer Vision is Boosting Mining's Productivity

With the rapid deployment of state-of-the-art AI technologies, enterprises are receiving more actionable data and insights than ever before, driving down their costs and enabling a safer and more productive work environment.

Read Blog →

Case Studies

Go to Part 2 - Material Handling