AI Mining: Unleash live & Hexagon Lead the Next Wave of Efficiency

In the evolving world of mining, data-driven precision is no longer a competitive edge—it’s a necessity! As global operations seek to reduce risk, increase output, and meet rising Environmental, Social and Governance (ESG) standards, intelligent automation is fast becoming the foundation of modern mine sites.

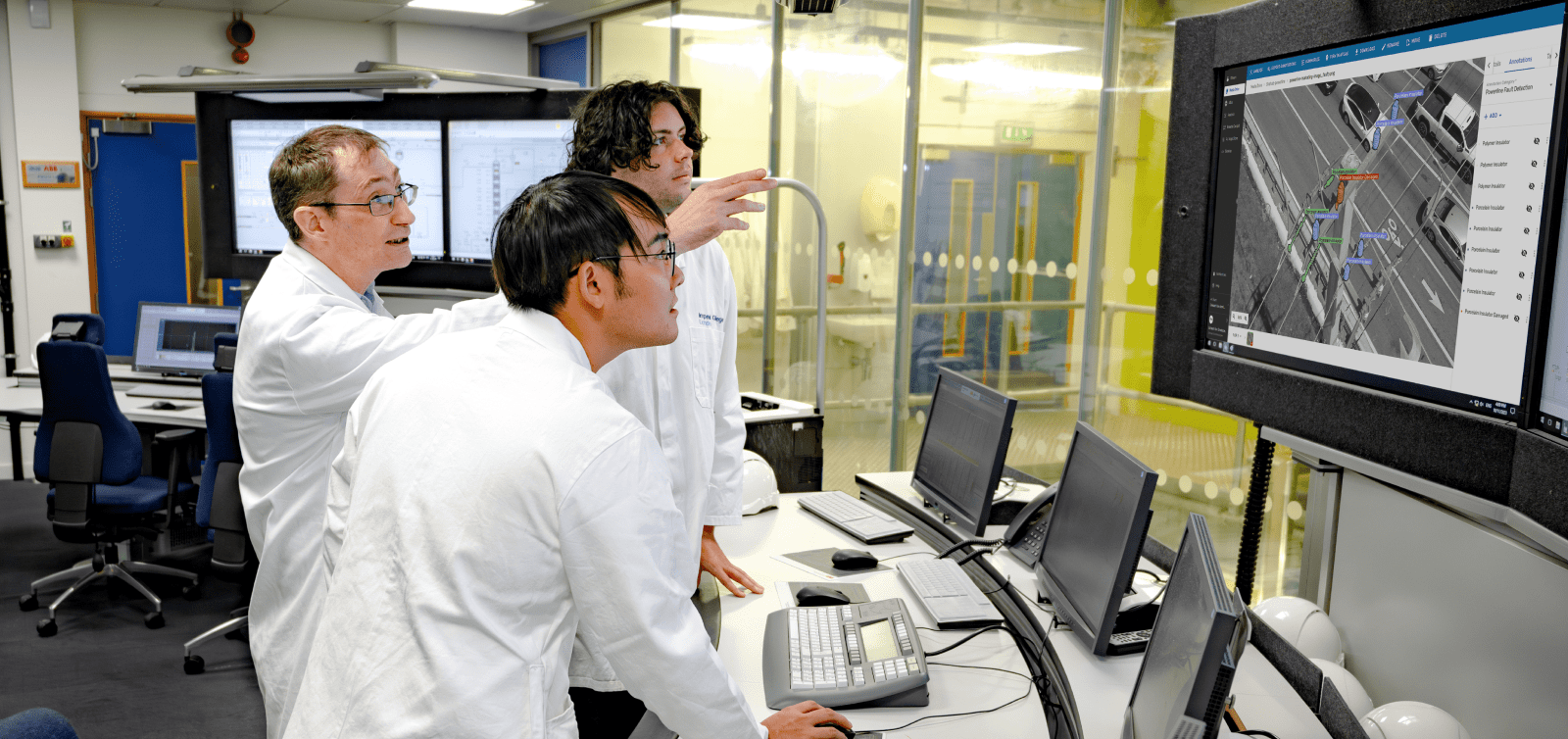

Enter Unleash live and Hexagon—two innovation leaders joining forces to reshape mining operations with real-time, Machine Learning AI analytics.

A Strategic Integration for Smarter Mining

Hexagon, a Sweden-based global leader in digital reality solutions, delivers advanced sensor, software, and autonomous systems across mining, manufacturing, and public safety sectors. With a mission to bridge the digital and physical worlds, Hexagon helps organisations harness complex spatial data to optimise productivity, improve safety, and operate more sustainably.

Through its strategic integration with Unleash live, Hexagon is extending its reach into powerful new territory—real-time video analytics. Unleash live’s AI platform transforms visual data from drones, CCTV, and industrial cameras into actionable insights that drive decision-making in the field.

Together, the two companies deliver an integrated analytics solution that merges Hexagon’s high-precision machine guidance with Unleash live’s real-time AI vision capabilities—bringing speed, automation, and intelligence to mining like never before.

Integrated workflow

Unleash live onboard systems connect with Hexagon mine ops box and allow real time flow of vision based alerts into the full mining operations. The integrations are configurable and alerts from the vision AI system can be mapped to specific alerts in the Hexagon mine ops system.

Real-Time Mining Use Cases

The collaboration unlocks a range of advanced solutions that enhance site awareness, equipment performance, and operational efficiency. Here’s some examples of how:

1. Oversize Rock Detection at the Crusher

Unleash live’s AI system identifies oversized rocks in real time—preventing them from being dumped into the wrong crusher and avoiding costly downtime. This solution eliminates the need for expensive depth cameras or LiDAR, using vision AI to calculate rock size with precision.

Now, with integration into Hexagon’s OP Pro Machine Guidance System, truck drivers receive live crusher routing directly on their in-cab screens—automating a decision that was previously manual and prone to error. Faster dumping cycles, reduced crusher blockages, and streamlined fleet coordination.

2. Excavator Tooth Fall Detection

When an excavator tooth breaks off, it can end up in a crusher and cause major equipment damage. Unleash live’s AI instantly detects missing teeth, triggering alerts so recovery teams can act before it becomes a costly incident.

3. Tailing Dam Monitoring

Using continuous video streams and machine learning, Unleash live helps operators track structural changes, water levels, and sediment movement around tailing dams—adding a layer of proactive risk management.

4. Dust Monitoring and Compliance

By integrating with site camera feeds, Unleash live’s AI measures dust levels across mine zones, supporting ESG reporting and real-time compliance with environmental thresholds.

Why This Matters: Reducing Downtime, Improving Safety

Without automation, many of these workflows depend on manual inspection or reactive decision-making. That means delays, errors, and increased risk. With AI-powered automation, the entire system becomes predictive, precise, and scalable.

Unleash live’s integration with Hexagon’s OP Pro ensures that these AI insights don’t just sit in dashboards—they’re embedded directly into operator workflows.

From excavators to haul trucks, decision-makers and drivers receive real-time guidance, all driven by AI.

The Future of Mining: Where Unleash live and Hexagon Go Next

The mining industry is shifting toward intelligent operations—powered by automation, connected systems, and AI insights. The Unleash live and Hexagon partnership is perfectly positioned to lead this transition.

Here’s what’s ahead:

1. Predictive and Prescriptive Analytics at Scale

- Combine historical data and real-time video to predict failures and prescribe actions

- Extend asset lifespan and reduce unplanned downtime

2. Autonomous Mining Workflows

- Fuse computer vision with Hexagon’s autonomous fleet management

- Move toward fully autonomous, human-supervised mine operations

3. AI-Driven Safety Intelligence

- Detect personnel in restricted zones

- Monitor PPE compliance and unsafe behavior

- Trigger real-time alerts to prevent accidents

4. Smart Material Flow and Inventory Tracking

- Use AI vision to identify material types and track them across the site

- Prevent bottlenecks and improve throughput

5. Sustainability and ESG Monitoring

- Capture emissions, water usage, and dust levels automatically

- Feed compliance reports with real-time visual evidence

6. Closed-Loop Quality Control in Manufacturing

- Integrate vision AI with Hexagon metrology tools

- Enable smart manufacturing lines with zero-defect feedback loops

Conclusion

The integration of Unleash live AI video analytics with Hexagon machine guidance systems represents a major leap in digital transformation for the mining industry. It closes the gap between what’s happening in the field and what decision-makers see—making operations safer, faster, and more efficient.

Mining teams no longer need to imagine what AI can do for them. With this partnership, they can experience it—live, in the field, and at scale.

Unleash live Mining Solutions:

Extraction

Material Handling

Mineral Processing

Hexagon Solutions:

Hexagon Products

Hexagon Op Pro Screen