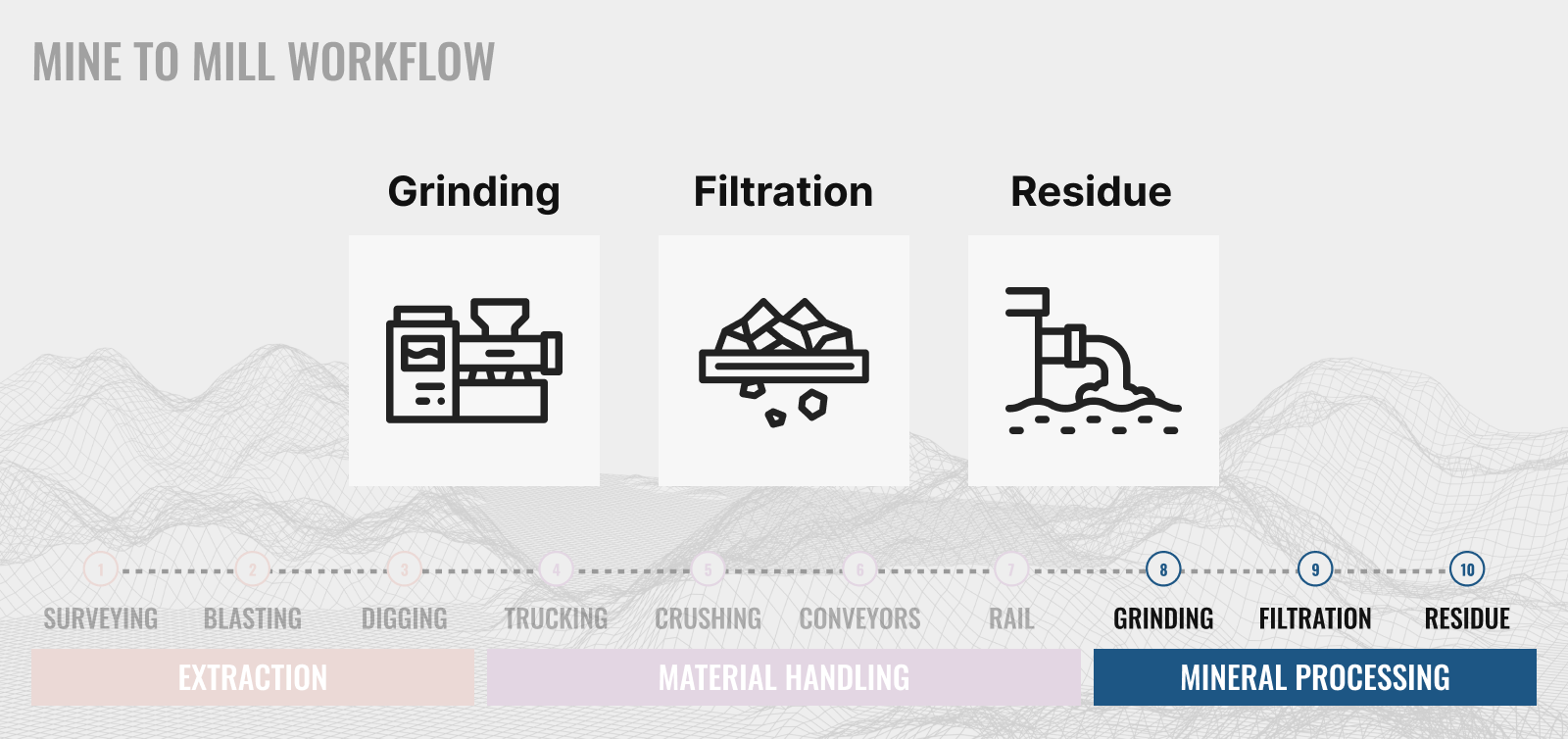

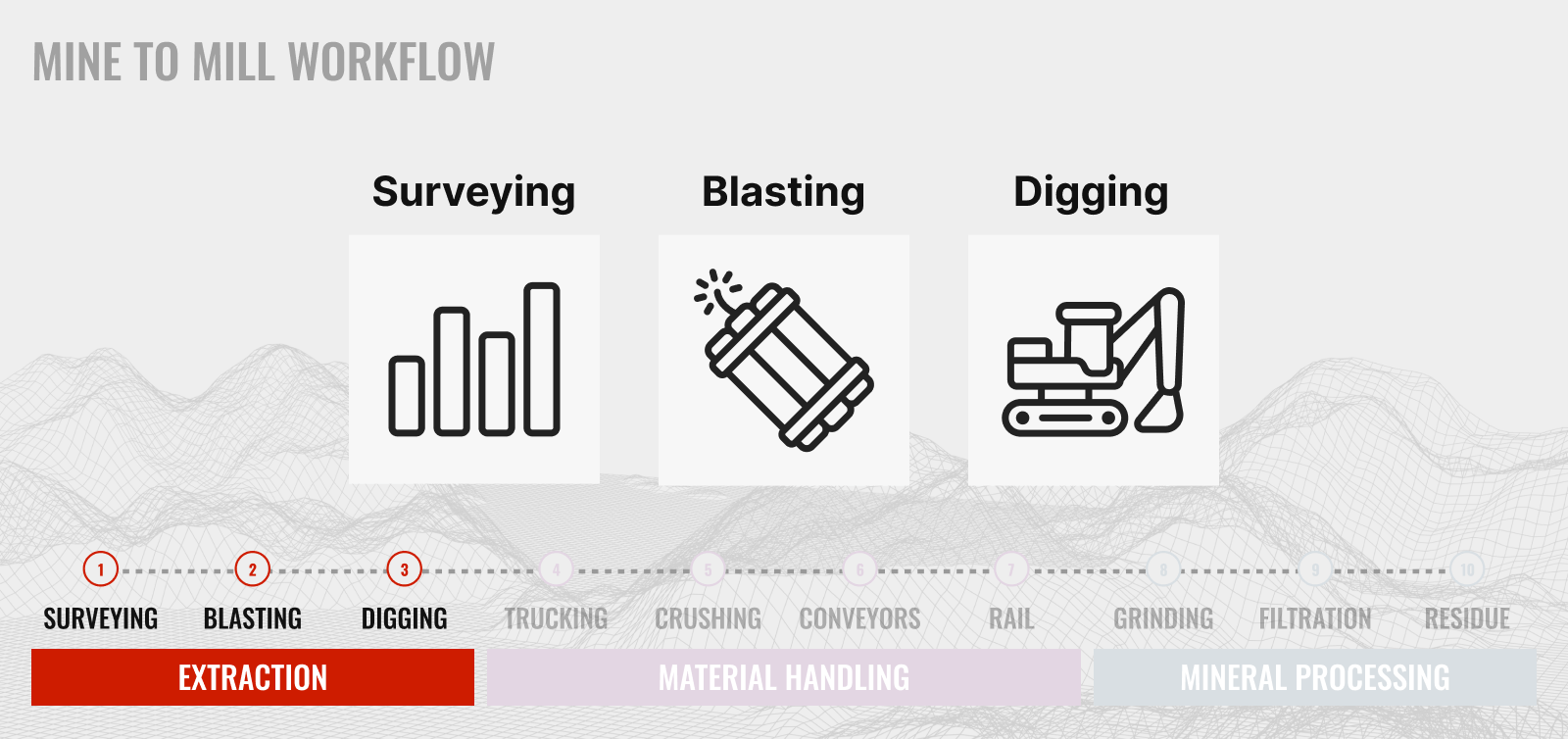

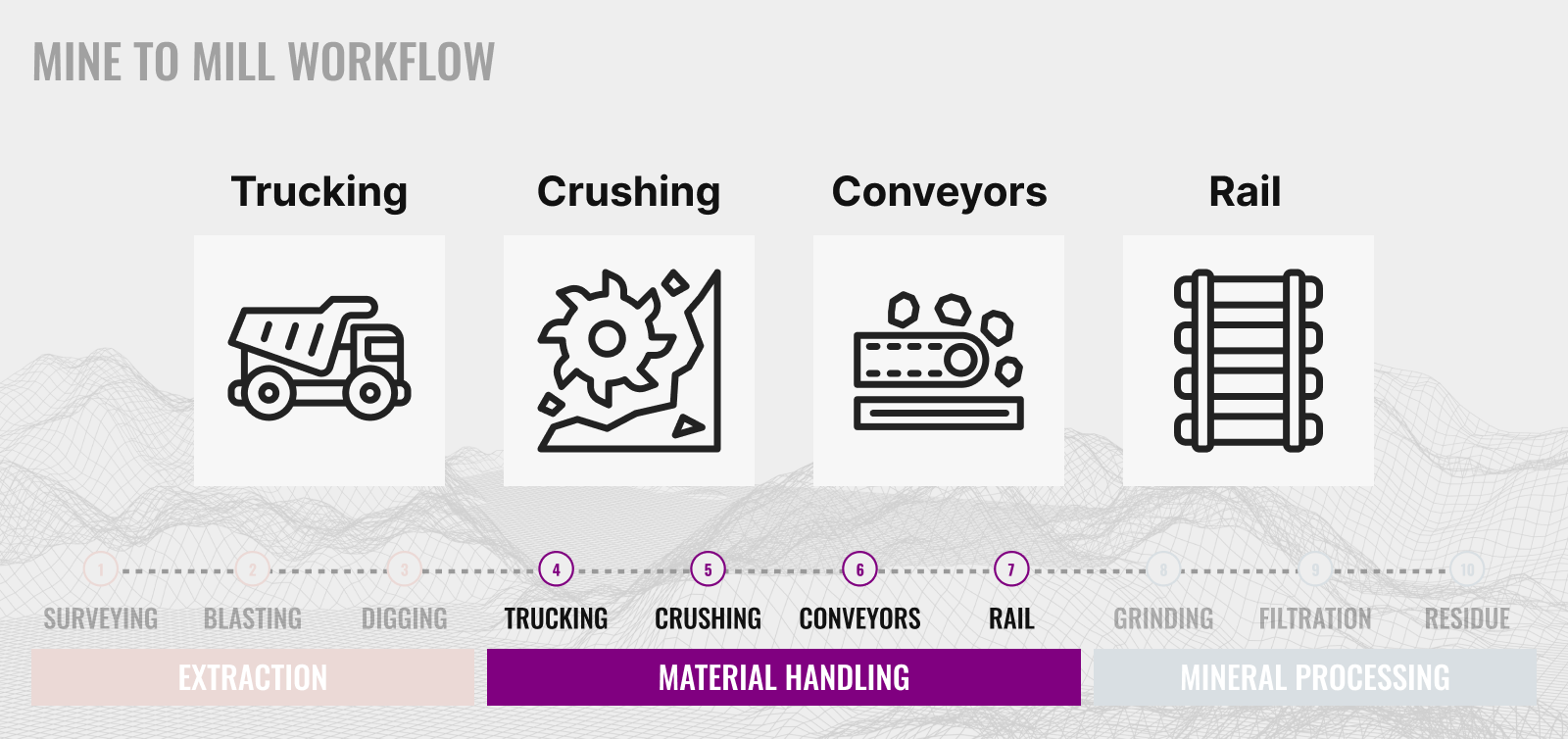

Digitizing Mine to Mill Workflows Series - Part 3 Mineral Processing

Workflow - Computer Vision for Improved Safety & Productivity

Introducing digital transformation for the entire mine-to-mill workflow. Unleash live's three-part series offers valuable insights into how we facilitate operational efficiency and safety within the resources industry.

Mine to Mill Workflow and Use Case Identification

Part 3: Mineral Processing - Grinding, Filtration & Residue

Discover how Unleash live's tailored approach can reduce downtime, improve safety, and increase throughput. In Part 3, 'Mineral Processing', we explore a range of use cases for computer vision with drones or IP cameras including:

- Mine shaft analytics

- Filter press health monitoring

- Tailing dam stability

- Flaring and venting

- Methane detection

- Containment loss

Streamline operations, improve asset performance and ensure the safety and sustainability of your mining endeavors quickly and effectively.

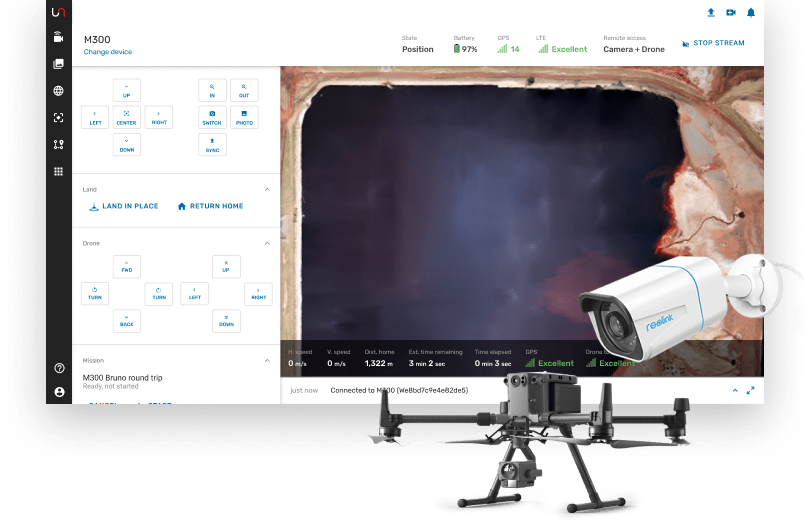

AI Video Analytics Process

- Collect: Operational data from live video streams using drones and IP cameras.

- Analyze: Turn manual visual inspections into automated, reliable, and action-based events using AI-driven analytics.

- Action: Inject real-time data into frontline operations for faster decision-making through integrated dashboards and alerts.

Run live streams or give remote operators camera or drone control

Collect

Operationalize live video from drones and IP cameras to take control

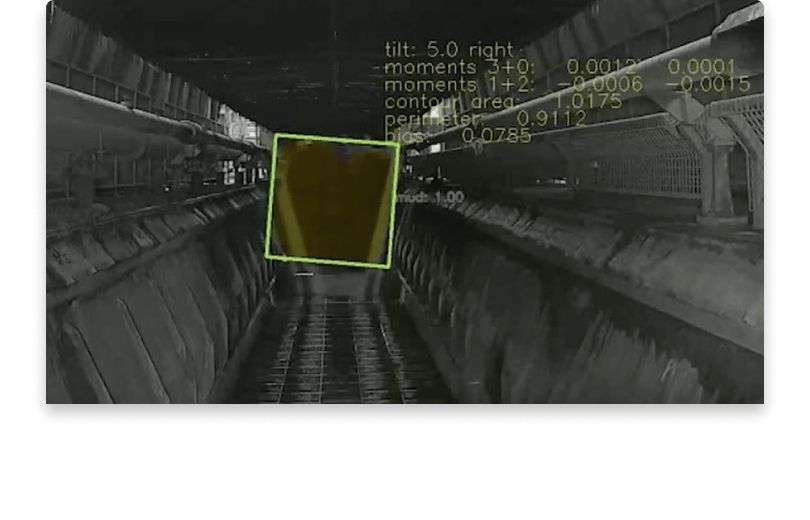

Filter Press AI Solution

Analyze

Turn manual visual inspections into automated, reliable and action based events

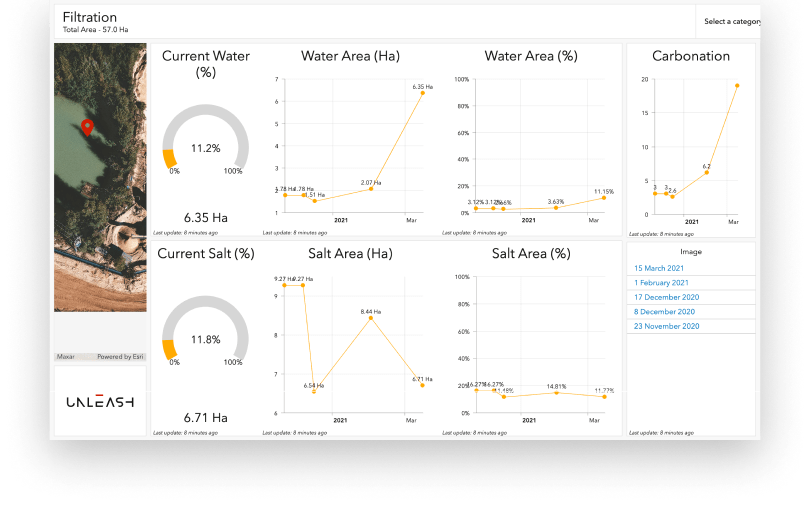

Dashboard on Tailings Dam condition and composition data

Action

Inject real-time data into your frontline operations for faster decision making through integrated dashboards and alerts.

Tailings Dam AI App Solution

Unlocking Efficiency and Sustainability

Carbon Analysis AI

Mining operations, particularly the management of tailings storage facilities (TSFs), demand precision and efficiency. Our client, a global leader in mining, recognized the challenges in accurately measuring salt and water content in their production process, leading to downstream issues and productivity concerns. Unleash live's AI solutions provided the necessary tools to address these challenges effectively.

Read more

Carbon Analysis AI

Unleash live's digital solutions optimize mine-to-mill workflows, enhancing safety and productivity in mineral processing with AI video analytics and tailored approaches.

Q&A

Q: How does Unleash live ensure the accuracy of its AI-driven inspections?

A: Our AI models are rigorously tested and continuously updated to ensure high accuracy. By leveraging vast amounts of data and sophisticated algorithms, we provide reliable and actionable insights.

Q: Can Unleash live's solutions be integrated with existing systems?

A: Yes, our solutions are designed to integrate seamlessly with your existing systems, allowing for a smooth transition and enhanced functionality without disrupting your current operations.

Q: What are the main benefits of using AI for mineral processing?

A: The main benefits include reduced downtime, improved safety, increased throughput, enhanced asset performance, and better decision-making through real-time data and analytics.

Q: How does Unleash live handle data privacy and security?

A: We prioritize data privacy and security by implementing robust measures such as SSL encryption, server-side encryption, and secure data storage practices. Our solutions comply with industry standards and regulations to protect your data.

Q: What types of cameras are compatible with Unleash live's AI solutions?

A: Our AI solutions are compatible with a wide range of IP cameras and drones, providing flexibility and scalability to meet your specific needs.

Q: How quickly can Unleash live's solutions be deployed?

A: Our solutions can be deployed rapidly, often within weeks, ensuring minimal disruption to your operations and quick realization of benefits.